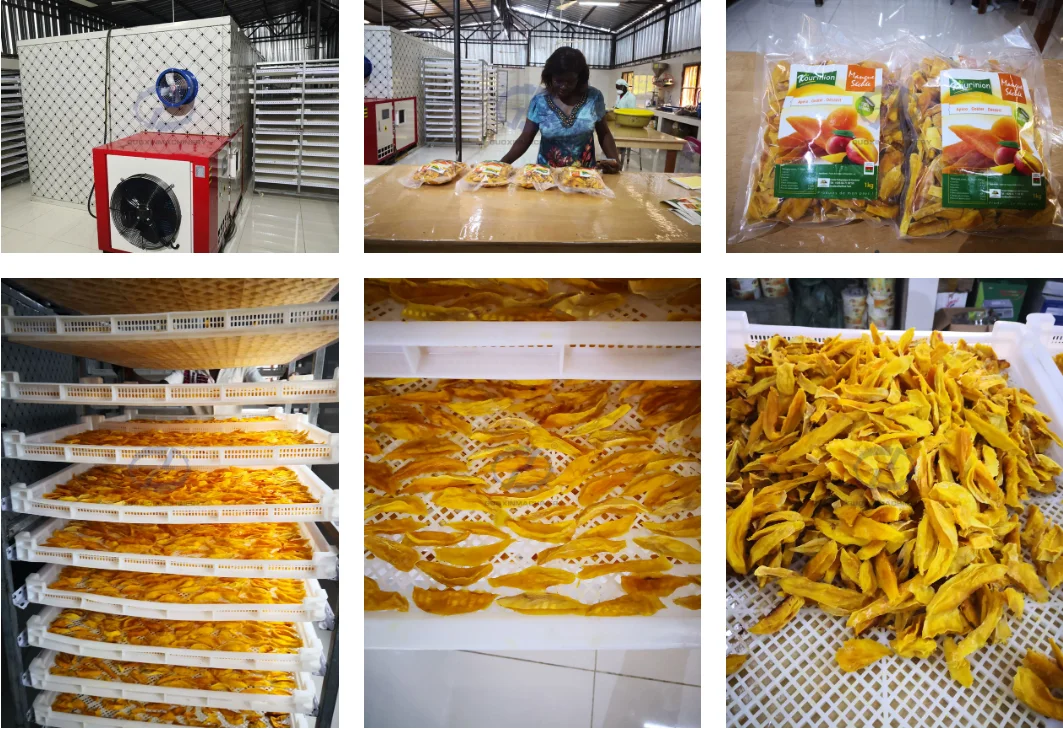

Mango Dryer Machine mango Drying Machine Drying Room Commercial Mango Dehydration Automated Dryer

(17 Lượt)

Công ty TNHH sản xuất máy móc Henan New Guoxin

Nhà sản xuất, chế tạo • 2 năm

VN

VN

Mango Dryer Machine mango Drying Machine Drying Room Commercial Mango Dehydration Automated Dryer

Các đề xuất khác cho doanh nghiệp của bạn

Những điểm chính về sản phẩm

Thuộc tính cụ thể của ngành

Các thuộc tính khác

Khu vực

Thương hiệu

Mã sản phẩm

Tên sản phẩm

Mango Dryer Machine mango Drying Machine Drying Room Commercial Mango Dehydration Automated Dryer

Nhà cung cấp

Công ty TNHH sản xuất máy móc Henan New Guoxin

Mô tả sản phẩm từ nhà cung cấp

Mô tả sản phẩm

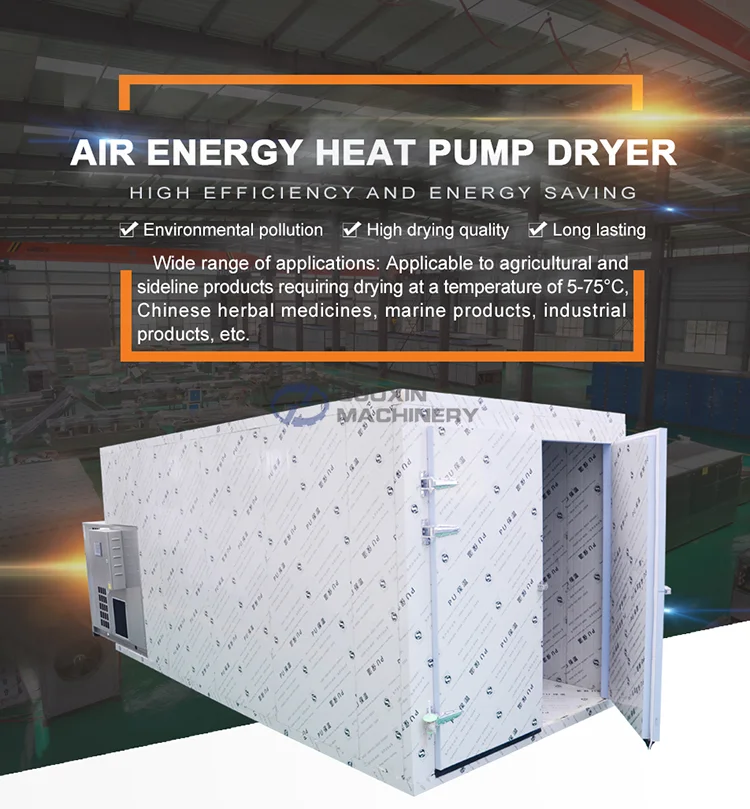

Product Description

Heat pump dryer advantages:

1. Stable performance,convenient operation,can achieve multi-functional,to meet different kinds of materials drying mode.

2. Adopting PLC programmable control mode, different drying curves can be set,such as: temperature,humidity and other settings,different drying curves can be set according to the material.

3. The heat pump in the heat pump drying device not only has the function of drying,but also has the function of refrigeration and heating,to achieve low temperature processing and greenhouse heating and other functions.

4. It has power failure memory function and one key setting to achieve intelligent management.

Fruit Nutritional Changes Occurred during Drying by Hot Air Drying Oven:

1. Calorie content: does not change, but is concentrated into a smaller mass as moisture is removed.

2. Fiber: no change.

3. Vitamin A: fairly well retained under controlled heat methods.

4. Vitamin C: mostly destroyed during drying of vegetables.

5. Minerals: some may be lost.

6. Iron: not be destroyed by drying.

Specification

Model | 3P | 5P | 8P | 15P | ||||

Heat Pump Size(L*W*H)mm | 1800*1000*1070 | 1800*1000*1070 | 1800*1000*1300 | 2150*1260*1620 | ||||

Drying Room Size(L*W*H)mm | 3300*2000*2200 | 3300*2000*2200 | 5600*2200*2700 | 8000*3000*2850 | ||||

Rated Heating Capacity (kw) | 10.75 | 12.25 | 23.2 | 49.65 | ||||

Host Power(kw) | 2.5 | 4 | 7.2 | 13.9 | ||||

Electric heating power(kw) | 6 | 6 | 12 | 24 | ||||

Circulating fan power(kw) | 8 x 0.25 | 8 x 0.25 | 12 x 0.25 | 12 x 0.75 | ||||

Returning Fan power(kw) | / | / | 3 x 0.25 | 3 x 0.75 | ||||

Humidity exhausting fan(kw) | 1 x 0.25 | 1 x 0.25 | 1 x 0.25 | 2 x 0.25 | ||||

Trolley Qty | 4 | 4 | 6 | 15 | ||||

Trolley size(mm) | 810*860*1750 | 810*860*1750 | 880*1200*1750 | 880*1200*1750 | ||||

Tray Qty | 96 | 96 | 144 | 360 | ||||

Tray Size(mm) | 430*730 | 430*730 | 600*800 | 600*800 | ||||

Tray Material | PP Polypropylene/Stainless Steel | |||||||

Friendly Tips: Equipment specifications can be customised | ||||||||

PACKING&SHIPPING

Company Profile

Established in 2005, Guoxin Machinery factory is a professional manufacturer of dryer, pretreatment equipment ,in Central China, with a modern complex occupying 5,000 square meters. With the support of dedicated employees and application of over 100 advanced machines, we have built a good reputation in the industry and successfully exported our high efficient dryers to more than 90 countries and regions, including Russia, central Asia, Brazil, the United States, Europe, Middle East and so forth.

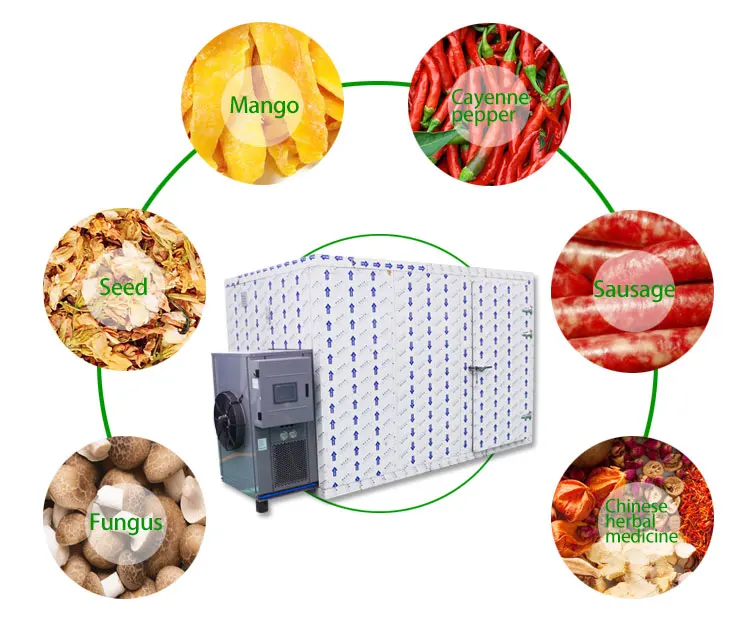

Our main products include: vegetable and fruit processing line,washing production line,french fries production line,Mesh-belt dryer,Heat pump dryer, Microwave drying sterilization equipment,freeze dryer and pretreatment products.

Those equipment is widely used in traditional Chinese herb, fruits, vegetables, food ,coconut,palm , other agricultural and industry products drying and processing, various models can meet the requirements of different kinds materials and different production scale.

FAQ

How is the quality of your products?

Our all products are certificated with CE quality inspection. Also manufactured strictly according to national and international standard, and we take a test on every machine before delivery.

What is your Business Model? Trading company or factory?

We are a 10 years factory, all our machinery are manufactured by ourselves, factory direct sales, product quality, and after-sales service can be guaranteed.

The installation time and how many people do you provide for us ?

Usually,our whole line equipment need 7-10 days for installation.

We will send one Qualified engineer go to customer working site installation debugging equipment, until the equipment can produce smoothly . The buyer should pay the engineer salary and round air tickets before engineer leaving seller factory. training buyer’s workers how to correct operation the drying machine.

Buyers need to in charge of :

(1) International air ticket fee.

(2) Service charge of Engineer: 150 USD per person per day.

(3) Accommodation and food.

How long for the warranty ?

100% brand new when leaving the factory. The seller guarantees quality of the machines for a period of one year from the date of trial run finish. If any part are found defective in quality in the first year, the seller should replace free-of-cost. Except the quick wear parts and Problems caused by improper operation.

Shipping/Vận chuyển

Dịch vụ chuyển phát nhanh toàn quốc (Tiêu chuẩn)

Thời gian giao hàng: Liên hệ

Bảo vệ cho sản phẩm này

Giao hàng qua Daisan Logistics

Giao hàng qua Daisan Logistics

Dự kiến đơn hàng của bạn sẽ được giao trước ngày dự kiến hoặc nhận khoản bồi thường chậm trễ 10%

Thanh toán an toàn

Thanh toán an toàn

Mọi khoản thanh toán bạn thực hiện trên Daisan.vn đều được ...

Chính sách hoàn tiền

Chính sách hoàn tiền

Yêu cầu hoàn lại tiền nếu đơn đặt hàng của bạn không được vận chuyển, bị thiếu hoặc giao đến có vấn đề về sản phẩm

Sản phẩm khác cùng danh mục

Sản phẩm có thể bạn quan tâm

Sản phẩm phổ biến của nhà cung cấp

Highperformance Metal Shredders Mini Metal Shredder Metal Recycling Machines Sorting Machine Waste

Liên hệ

1 piece (Tối thiểu)

OEM Coconut Shell Crusher Portable Metal Shredder Garbage Crushing Machine Waste Management System

Liên hệ

1 piece (Tối thiểu)

OEM Highperformance Metal Shredders Metal Waste Shredding and Grinding Equipment Sorting Machine Waste

Liên hệ

1 piece (Tối thiểu)

Professional Food Drying Machine Mesh Belt Tunnel Dryer Industrial Food Dehydrated

Liên hệ

1 piece (Tối thiểu)

Highperformance Metal Shredders Scrap Metal Recycling Equipment Metal Sorting System Sorting Machine Waste

Liên hệ

1 piece (Tối thiểu)

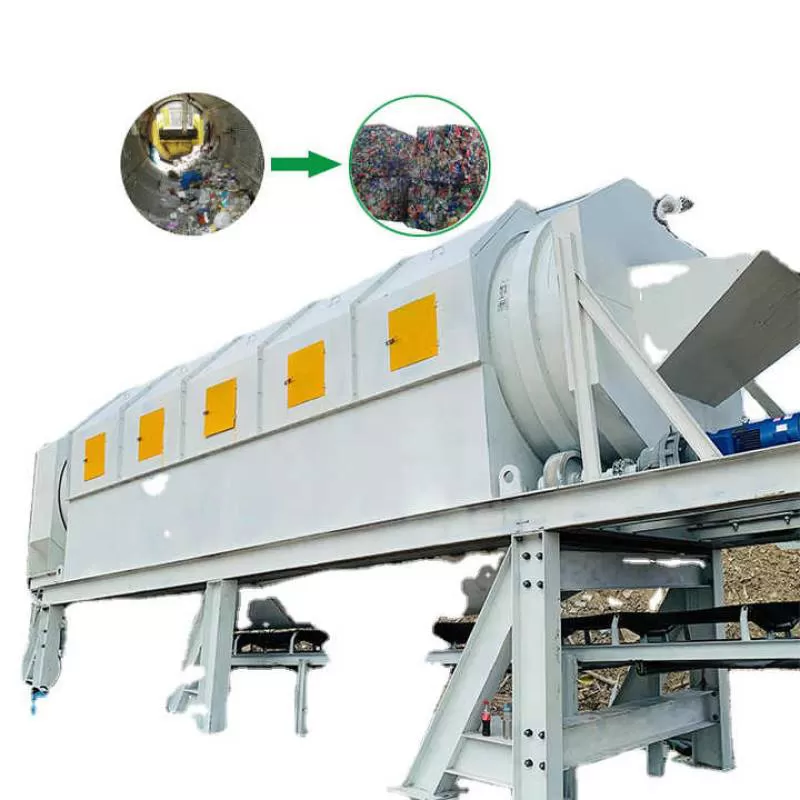

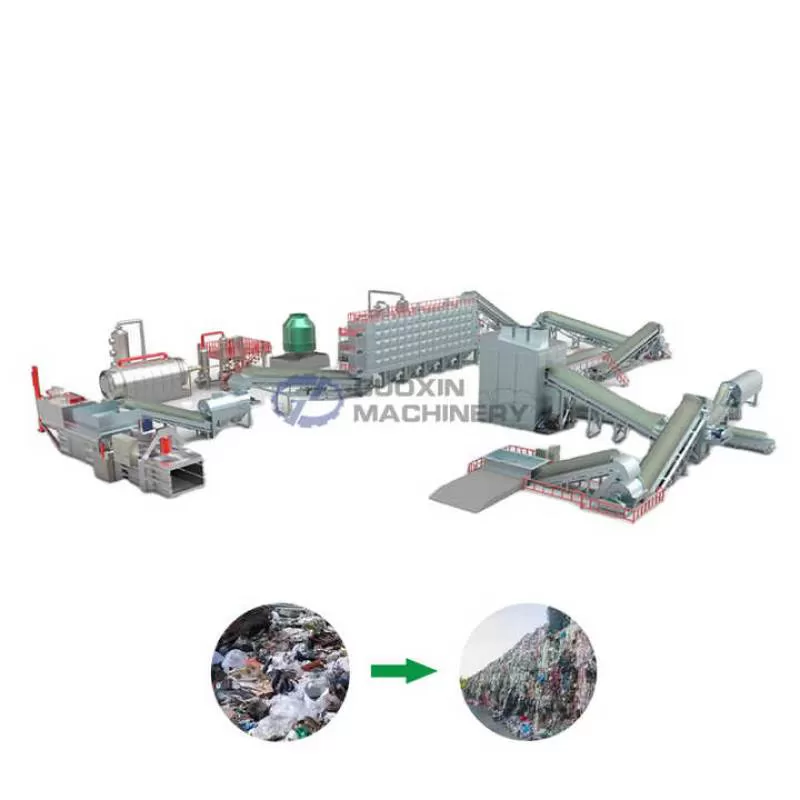

Landfill Stale Waste Sorting Machine Waste Separation and Recycling Solutions and Equipment

Liên hệ

1 piece (Tối thiểu)

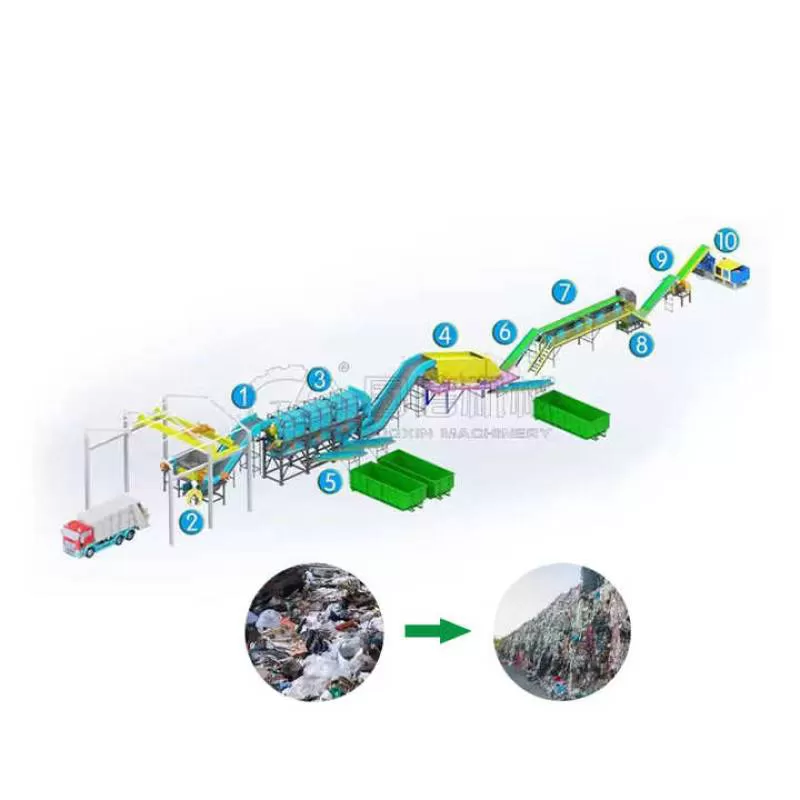

OEM on Sale Automatic Waste Segregation Machine Waste Management in Big Cities Municipal Waste Sorting Line

500,000,000đ

1 piece (Tối thiểu)

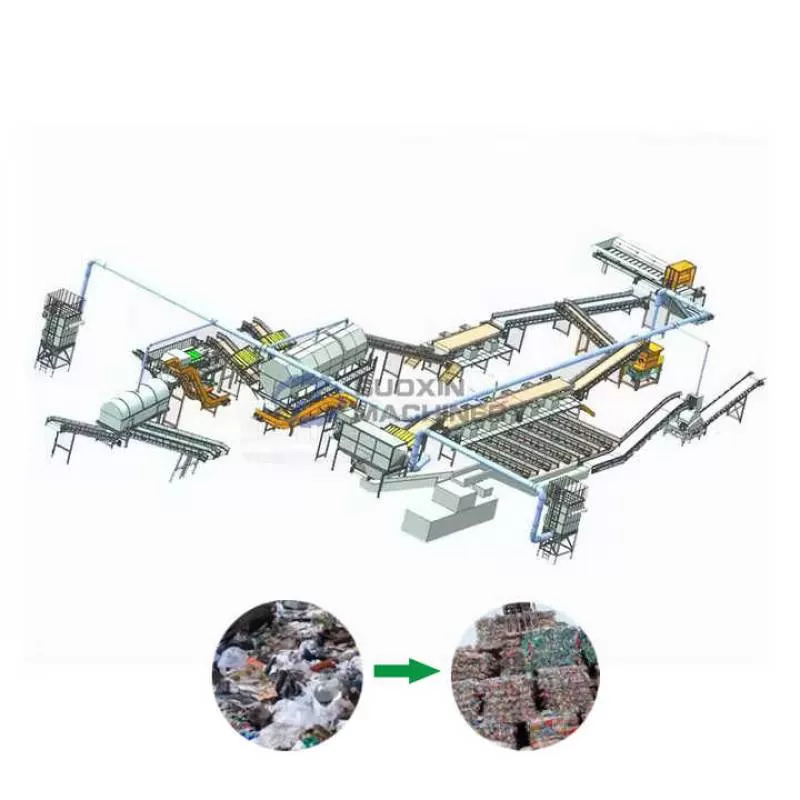

OEM on Sale Automated Waste Sorting System Waste Management Facility Urban Waste Sorter Plastic Sorting Machine

500,000,000đ

1 piece (Tối thiểu)

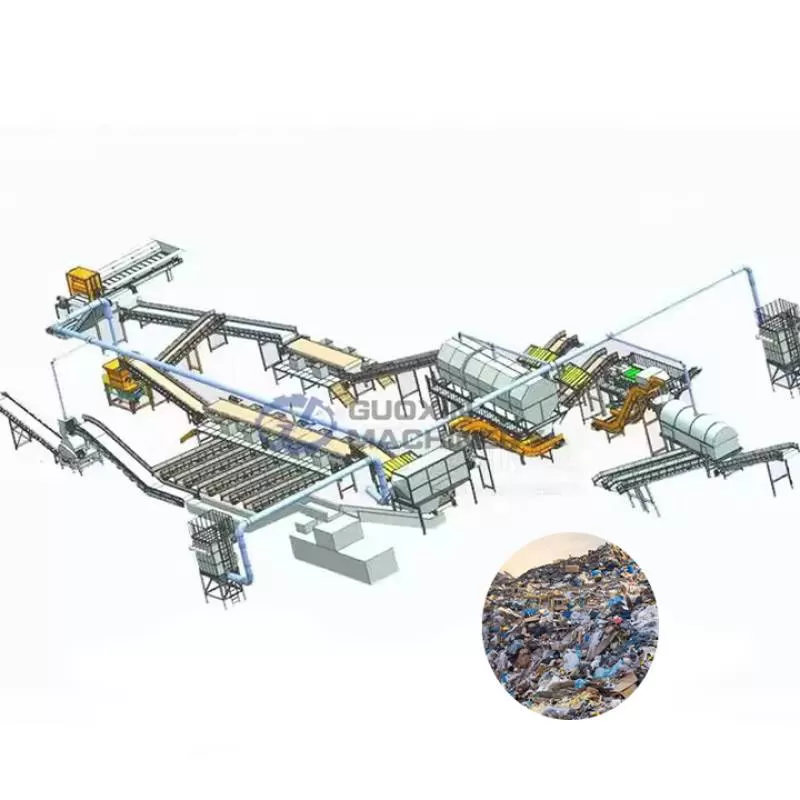

Municipal Solid Waste Sorting Machine Recycling High Efficiency Garbage Sorting Waste Screening Equipment

500,000,000đ

1 piece (Tối thiểu)

Large-capacity Mobile Mesh Belt Drying Device Food Spices Dryer Vine Pepper Drying And Dehumidify Equipment

500,000,000đ

1 piece (Tối thiểu)