OEM Trommel Screen Specifications Garbage Drum Screen Sorting Compost Rotary Trommel Large Capacity Trommel Rotary Drum Screen

(17 Lượt)

Công ty TNHH sản xuất máy móc Henan New Guoxin

Nhà sản xuất, chế tạo • 2 năm

VN

VN

OEM Trommel Screen Specifications Garbage Drum Screen Sorting Compost Rotary Trommel Large Capacity Trommel Rotary Drum Screen

Các đề xuất khác cho doanh nghiệp của bạn

Những điểm chính về sản phẩm

Thuộc tính cụ thể của ngành

Các thuộc tính khác

Khu vực

Thương hiệu

Mã sản phẩm

Tên sản phẩm

OEM Trommel Screen Specifications Garbage Drum Screen Sorting Compost Rotary Trommel Large Capacity Trommel Rotary Drum Screen

Nhà cung cấp

Công ty TNHH sản xuất máy móc Henan New Guoxin

Mô tả sản phẩm từ nhà cung cấp

Mô tả sản phẩm

Product Description

OEM Trommel Screen Specifications Garbage Drum Screen Sorting Compost Rotary Trommel Large Capacity Trommel Rotary Drum Screen

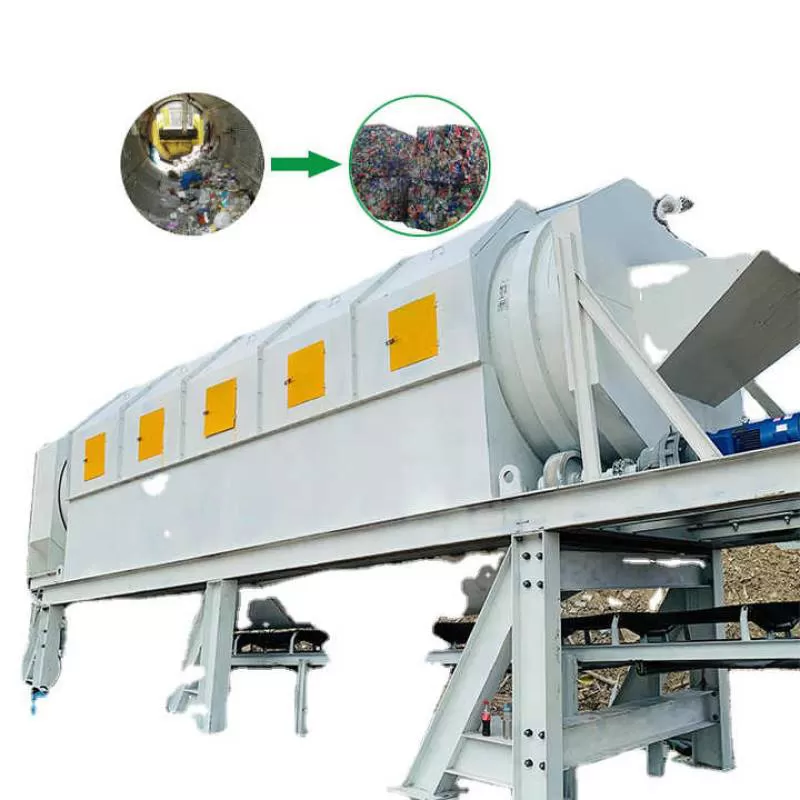

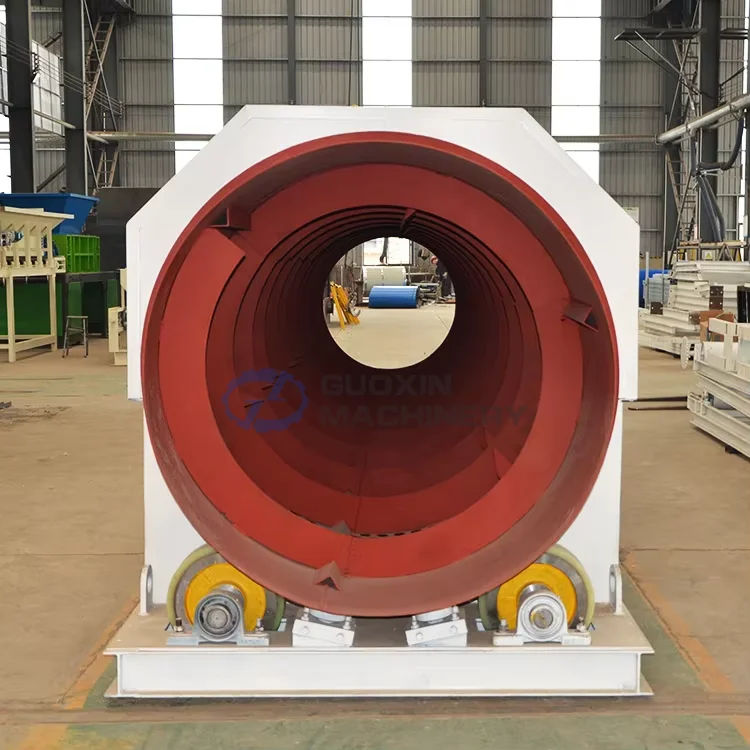

The drum screening machine is a key piece of equipment in the comprehensive processing line. It mainly consists of a electric motor, gear reducer, drum, frame, support frame, sealed protective cover, feed hopper, lower hopper, and discharge hopper. It features a shaftless design with roller support for drum rotation, making it suitable for screening materials of various particle sizes, such as construction and demolition waste, municipal solid waste, Stale landfill waste, stone, coal, slag, and mineral residue.

The drum screening machine series, designed and manufactured by our company, offers strong screening capability, superior performance, high adaptability to working conditions, convenient screen plate replacement, and easy maintenance.

The drum body is made of 16Mn steel plate and features a thick-walled rotating drum structure, ensuring smooth operation, stable conveying speed, and low noise (≤85dB). The gears mesh well, and the feed and discharge systems are tightly sealed to prevent material leakage or spillage.

The entire equipment is resistant to acid, alkali, and corrosion. Critical components, such as the structural framework, undergo surface reinforcement treatment. The load-bearing wheel series is made of high-quality wear-resistant materials, with an outer layer coated in polyester composite material for enhanced wear resistance, pressure resistance, and acid-alkali resistance.

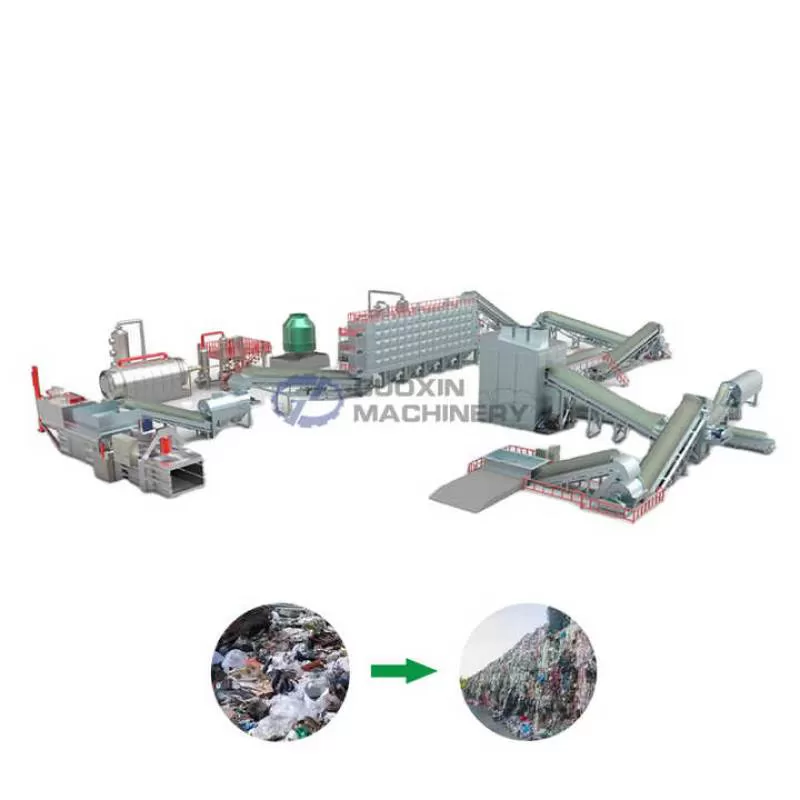

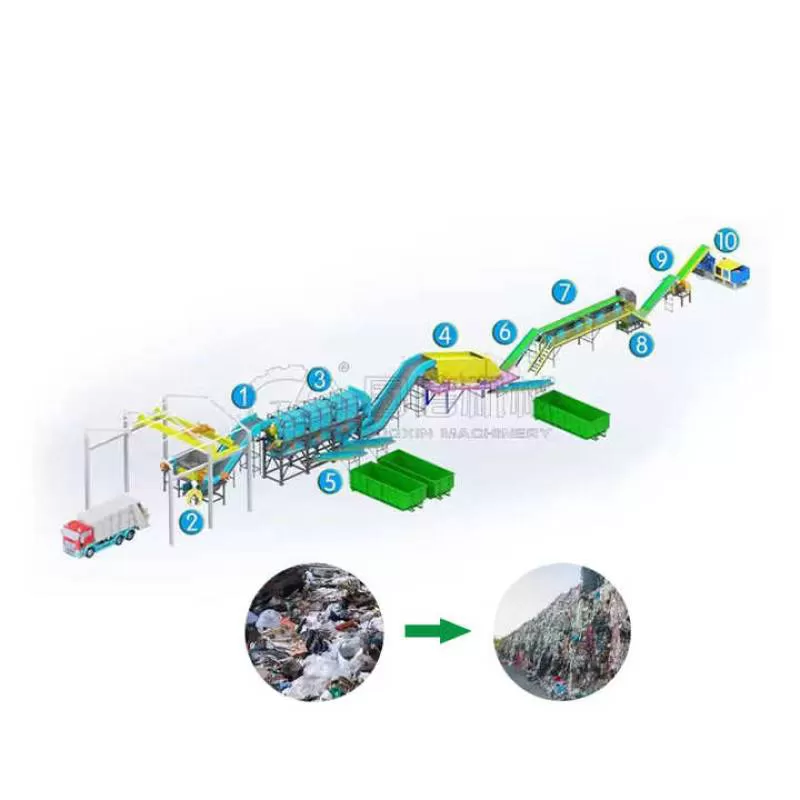

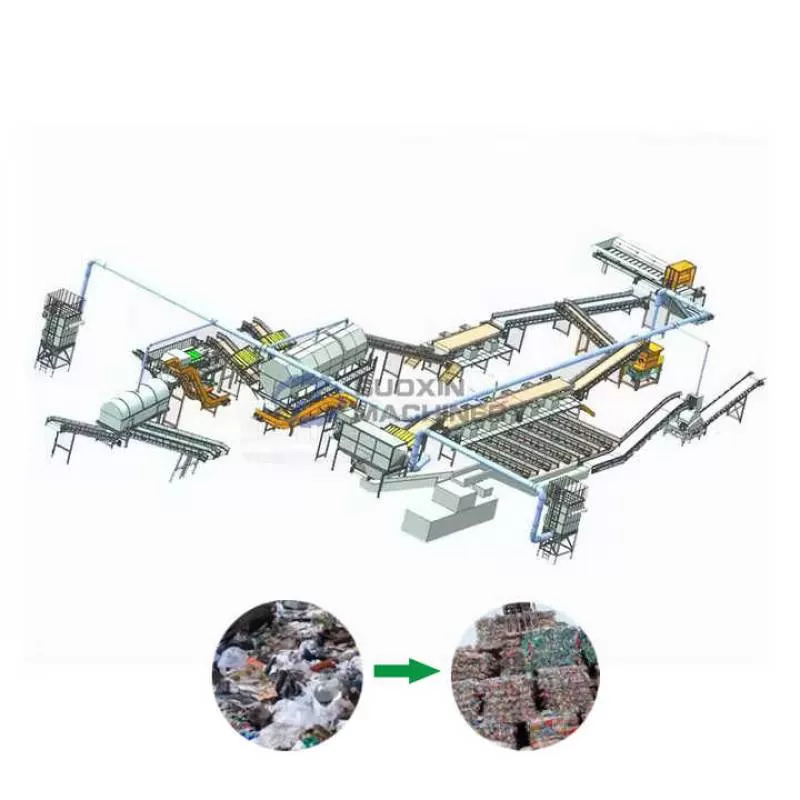

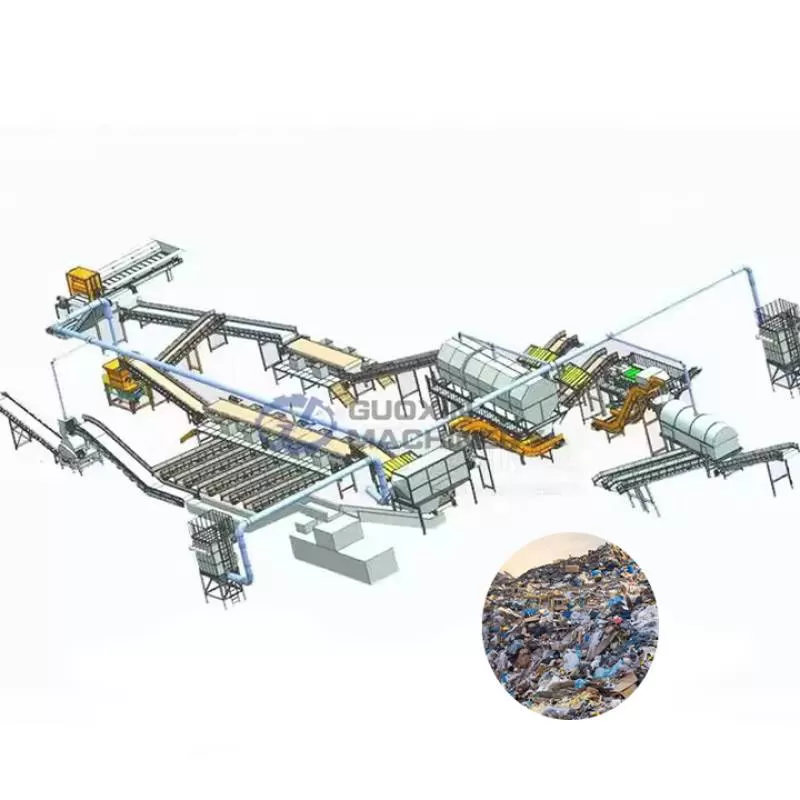

Assembly Line

Discover the full range of products from our assembly line

The waste material is fed into a chain conveyor feeder, which directs it to a drum screening machine, magnetic separator, air separator, or other waste sorting equipment to separate metals, wood, plastics, building aggregates, and other materials. The sorted metal, wood, plastic, and paper can then be processed for recycling.

• Garbage of Urban Life: Includes waste paper (stacked paper bales), plastics (mixed plastic debris), cans (assorted metal cans), and textiles (piled clothing and fabric scraps)—common household and urban waste streams we efficiently sort and recycle.

• Solid Construction Waste: Encompasses plastics (construction-related plastic waste), waste wood (wooden planks and scraps), soil (loose earthy material), and concrete (broken concrete fragments and rubble)—key materials from construction and demolition sites that we transform into reusable resources.

• Industrial Solid Waste: Features waste iron (tangled metal scraps) and other industrial byproducts, which our advanced systems recover and repurpose.

Please do not hesitate to contact us if you require further information about any other components of our construction and renovation waste sorting and processing line.

Case Studies

Specification

item | value |

type | Sorting and Recycling Facilities |

warranty | 1 Year |

material | Municipal Solid Waste, Construction and Renovation Debris, etc. |

weight (kg) | 20000 |

Power | 160 Kw |

place of origin | China |

Henan | |

brand name | Guoxin Machinery |

model number | GX-TS |

machinery test report | Provided |

video outgoing-inspection | Provided |

core components | Electric Motor, Gear Reducer, Drum, Frame, Support Frame, Sealed Protective Cover, Feed Hopper, Lower Hopper, Discharge Hopper. |

Name | Sorting and Recycling Facilities |

Certification | CE; ISO |

Raw material | Municipal Solid Waste, Construction and Renovation Debris, etc. |

Color | Customisable |

After-sales Service Provided | On-site Service |

Usage | Waste Treating |

Function | Garbage Recycling Sorting |

Keywords | Waste Recycling Plant Sorting |

Capacity | Customisable |

Technology | Air Separation |

About Us

Through continuous innovation and partnerships with industry leaders, we have developed extensive expertise in sorting and processing a diverse array of materials and by-products, including plastics, metals, paper, glass, organic waste, and more. Dedicated to providing exceptional quality and service, we actively track market trends and customer requirements, enhancing our recycling techniques and facility operations to address the evolving needs of sustainable waste management.

PACKING&SHIPPING

Shipping fees and delivery schedules are flexible and can be negotiated. Please feel free to contact us for further details. We are committed to providing the most reliable and cost-effective delivery solutions tailored to your needs.

FAQs

How would you rate the quality of your products?

All of our products are CE certified and are manufactured in strict compliance with both national and international standards. Furthermore, we conduct thorough testing on each machine before delivery to ensure optimal quality.

What is your business model? Are you a trading company or a factory?

We are a factory with 10 years of experience in manufacturing. All of our machinery is produced in-house, allowing us to offer direct sales from the factory. This ensures that we can guarantee both the quality of our products and our after-sales service.

Can I visit your factory?

Certainly, we regularly host both domestic and international clients at our factory. Our facility is located in Zhengzhou, Henan Province, China, and is easily accessible by air or train. The nearest airport is Zhengzhou Xinzheng Internaional Airport (CGO). We will arrange transportation to pick you up from the airport and take you to our factory. We look forward to your visit.

What is the installation time and how many people will your provide?

Typically, the installation of our entire equipment line takes 7-10 days. We will send one qualified engineer to the customer's site to install and debug the equipment, ensuring it operates smoothly. The customer will be responsible for covering the engineer's salary and round-trip airfare before the engineer leaves the factory.

Additionally, the engineer will provide training for the buyer's staff on the correct operation of the drying machine.

The buyer will be responsible for:

1. The cost of international airfare

2. The service charge for the engineer, which is $150 USD per day.

3. Accommodation and meals for the engineer.

What is the warranty period?

The machines are 100% brand new when they leave our factory. We guarantee the quality of the equipment for one year from the completion of the trial run. If any parts are found to be faulty within the first year, we will replace them free of charge, except for parts subject to standard wear and tear and damages caused by improper operation.

All of our products are CE certified and are manufactured in strict compliance with both national and international standards. Furthermore, we conduct thorough testing on each machine before delivery to ensure optimal quality.

What is your business model? Are you a trading company or a factory?

We are a factory with 10 years of experience in manufacturing. All of our machinery is produced in-house, allowing us to offer direct sales from the factory. This ensures that we can guarantee both the quality of our products and our after-sales service.

Can I visit your factory?

Certainly, we regularly host both domestic and international clients at our factory. Our facility is located in Zhengzhou, Henan Province, China, and is easily accessible by air or train. The nearest airport is Zhengzhou Xinzheng Internaional Airport (CGO). We will arrange transportation to pick you up from the airport and take you to our factory. We look forward to your visit.

What is the installation time and how many people will your provide?

Typically, the installation of our entire equipment line takes 7-10 days. We will send one qualified engineer to the customer's site to install and debug the equipment, ensuring it operates smoothly. The customer will be responsible for covering the engineer's salary and round-trip airfare before the engineer leaves the factory.

Additionally, the engineer will provide training for the buyer's staff on the correct operation of the drying machine.

The buyer will be responsible for:

1. The cost of international airfare

2. The service charge for the engineer, which is $150 USD per day.

3. Accommodation and meals for the engineer.

What is the warranty period?

The machines are 100% brand new when they leave our factory. We guarantee the quality of the equipment for one year from the completion of the trial run. If any parts are found to be faulty within the first year, we will replace them free of charge, except for parts subject to standard wear and tear and damages caused by improper operation.

Services

Pre-Sales Services

1. Our professional engineers design a customized production line to meet your needs.

2. we recommend the most suitable equipment based on your specific requirements.

3. 24/7 online consulting services are available

Mid-Sales Services

1. We conduct thorough inspections of all products before delivery

2. Our technicians are available to guide installation and system adjustments on-site.

3. We provide operator training and ensure all systems meet your requirements before completion.

Post-Sales Services

1. Common issues can be resolved online within 24 hours, while more complex problems will be addressed immediately and resolved as soon as possible.

2. To foster long-term partnership, we maintain regular contact with our customers.

3. We offer ongoing technical consulting services.

2. we recommend the most suitable equipment based on your specific requirements.

3. 24/7 online consulting services are available

Mid-Sales Services

1. We conduct thorough inspections of all products before delivery

2. Our technicians are available to guide installation and system adjustments on-site.

3. We provide operator training and ensure all systems meet your requirements before completion.

Post-Sales Services

1. Common issues can be resolved online within 24 hours, while more complex problems will be addressed immediately and resolved as soon as possible.

2. To foster long-term partnership, we maintain regular contact with our customers.

3. We offer ongoing technical consulting services.

Giá

450,000,000 đ

Shipping/Vận chuyển

Dịch vụ chuyển phát nhanh toàn quốc (Tiêu chuẩn)

Thời gian giao hàng: Liên hệ

Bảo vệ cho sản phẩm này

Giao hàng qua Daisan Logistics

Giao hàng qua Daisan Logistics

Dự kiến đơn hàng của bạn sẽ được giao trước ngày dự kiến hoặc nhận khoản bồi thường chậm trễ 10%

Thanh toán an toàn

Thanh toán an toàn

Mọi khoản thanh toán bạn thực hiện trên Daisan.vn đều được ...

Chính sách hoàn tiền

Chính sách hoàn tiền

Yêu cầu hoàn lại tiền nếu đơn đặt hàng của bạn không được vận chuyển, bị thiếu hoặc giao đến có vấn đề về sản phẩm

Sản phẩm khác cùng danh mục

Sản phẩm có thể bạn quan tâm

Sản phẩm phổ biến của nhà cung cấp

Highperformance Metal Shredders Mini Metal Shredder Metal Recycling Machines Sorting Machine Waste

Liên hệ

1 piece (Tối thiểu)

OEM Coconut Shell Crusher Portable Metal Shredder Garbage Crushing Machine Waste Management System

Liên hệ

1 piece (Tối thiểu)

OEM Highperformance Metal Shredders Metal Waste Shredding and Grinding Equipment Sorting Machine Waste

Liên hệ

1 piece (Tối thiểu)

Professional Food Drying Machine Mesh Belt Tunnel Dryer Industrial Food Dehydrated

Liên hệ

1 piece (Tối thiểu)

Highperformance Metal Shredders Scrap Metal Recycling Equipment Metal Sorting System Sorting Machine Waste

Liên hệ

1 piece (Tối thiểu)

Landfill Stale Waste Sorting Machine Waste Separation and Recycling Solutions and Equipment

Liên hệ

1 piece (Tối thiểu)

Mango Dryer Machine mango Drying Machine Drying Room Commercial Mango Dehydration Automated Dryer

Liên hệ

1 piece (Tối thiểu)

OEM on Sale Automatic Waste Segregation Machine Waste Management in Big Cities Municipal Waste Sorting Line

500,000,000đ

1 piece (Tối thiểu)

OEM on Sale Automated Waste Sorting System Waste Management Facility Urban Waste Sorter Plastic Sorting Machine

500,000,000đ

1 piece (Tối thiểu)

Municipal Solid Waste Sorting Machine Recycling High Efficiency Garbage Sorting Waste Screening Equipment

500,000,000đ

1 piece (Tối thiểu)