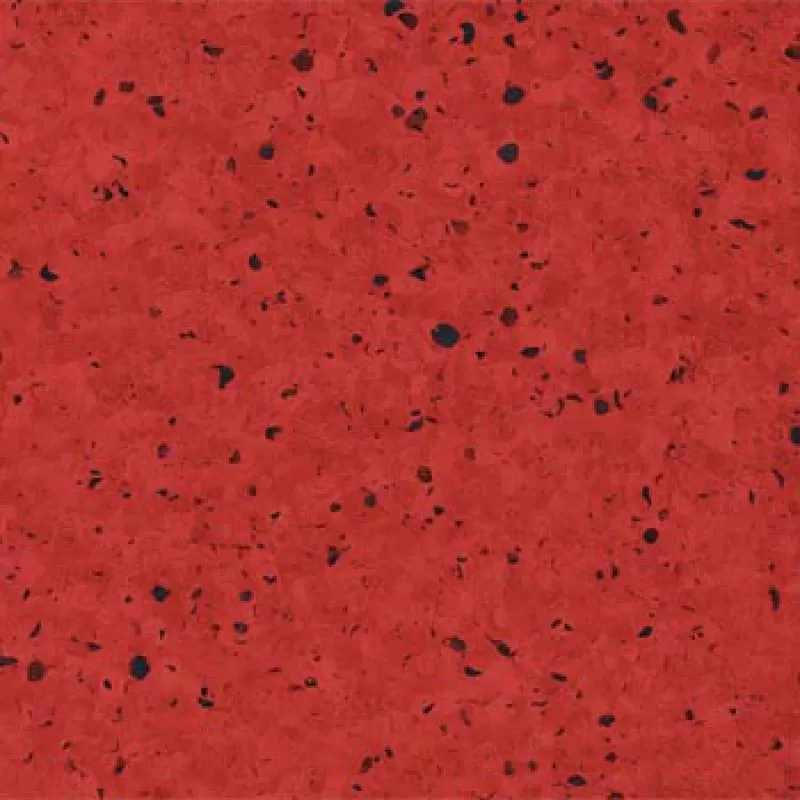

Sàn Vinyl Chống Tĩnh Điện ESD

Sàn Vinyl Chống Tĩnh Điện ESD

Các đề xuất khác cho doanh nghiệp của bạn

Những điểm chính về sản phẩm

Thuộc tính cụ thể của ngành

Các thuộc tính khác

Mô tả sản phẩm từ nhà cung cấp

Mô tả sản phẩm

The floor uses the PVC resin as the main component, and utilizes the plastic particle interfaces to form the permanent conductive/anti-static network. The floor tile is looked like the marble. It provides fine performance in the decoration projects. In addition, they feature abrasion resistance, corrosion resistance, long life, ageing resistance and low dust emission etc.

Conductive PVC floor tile:2.5x104-1x106

Static-dissipative PVC floor tile:1x106-1x109

Size:600x600mm, 610x610mm Thickness:2mm, 2.5mm, 3mm even 5.0mm

Features:Hardwearing homogeneous contract tile floor covering

Technical Specification

| Item | Standard | Index | Item | Standard | Index |

| Thickness | EN428 | 2.0mm,2.5mm,3.0mm | Size | EN426 | 600x600mm |

| Fire resistance grade | DIN4102 | B1 | Combustion property | GB460984 FV-0 | <10s |

| Emission quantity | Nordtest NT Build358/1 | after14 week TVOC<200µg | Charge Decay time | GJB2605 | <2S |

| Sound resistance | ISO&DIN | ΔLw is about 2dB | Chargeability | SJ/T10694 | <100V |

| Dimensional stability | EN434 | distortion < 0.1% | Rate of size change at heating | GB4085 | <0.25% |

| Pressure vestige | EN443,after 2.5 hours | < 0.05mm | Colligation resistance value(shoe/floor) | IEC61340-5-1 | <35MΩ |

| Truckle grind vestige | EN425 | suitable,0mm | Seaming strength | EN684 | >240N/50mmΩ |

| Abrasion resistance | EN660Pt2 | T grade,< 2.0mm3 | Anti-Wear | GB4085 | <0.02g/cm2 |

Electrical Character

| Item | Test Standard | Conducting Tile | Static-Dissipative Tile |

| STG(surface to ground) resistance (Ω) | UL-779 | 2.5×104-1×106 | 1×106-1×109 |

| STS(surface to surface) resistance(Ω) | UL-779 | 2.5×104-1×106 | 1×106-1×109 |

| Static 5kv decay time(sec) | MIL-B-81705C | <0.25 | |

| Static generation (Volts) with conductive footwear | AATCC-134 | <100 | |

Chemical/Contaminant Resistance

| Chemical Products | Conductive Capability | Contaminant | Conductive Capability |

| 5% Acetic acid | no influenced | Soya bean oil | no influenced |

| 5% Hydrochloric acid | no influenced | Coal oil | no influenced |

| 5% Nitric acid | no influenced | Cement paste | no influenced |

| 5% Ammonia liquor | no influenced | Milk | no influenced |

| 95% Alcohol | no influenced | Soy Sauce | no influenced |

Test

Ground testing apparatus of electrostatic prevention PVC should accord with demand of “ staple testing apparatus”

Testing environment: Temperature should be among 15-30℃; The relative temperature should be smaller than 70%.Surface resistance value and Measurement of the systematic resistance value of electrostatic prevention PVC ground should adopt following testing ways:

1.Testing of surface resistance: whole electrostatic prevention ground should cut into 2-4m2,measure area: random access 30%-50% testing area, Put two electrodes into sticking panel surface separately, The interval is 900mm,. Contact electrode and panel are good. Should measure 4-8 numerical value in 2-4 m2 and note down.

2.Measurement of the systematic resistance: The area where should be nearest to every ground terminal, collect several points at random, Should contact an electrode well with the surface which sticks the panel, Another electrode links with earth port to form, Measure systematic resistance value and note down.

3.Quality assess method should perform according to GB2828<< stepwise examine sample procedure and sample form >>

The electric performance index should accord with the following demand:

1.Demand to have static leading type, its surface resistance and systemic resistance value are lower than 1.0×106Ω。

2.Demand to have static dissipating type, its surface resistance and systemic resistance value are between 1.0×106-1.0×109Ω.

3.Systemic earth resistance value should satisfy the design requirement.

Appearance performance should accord with the following demands:

1.Can't appear hollowing, delamination, and chap phenomenon;

2.Don't have any obvious bumps and holes;

3.Don't have any obvious scars;

4.Don't have any obvious aberrations

The unit that carries on the ground testing of electrostatic prevention PVC should gain corresponding testing report qualification.