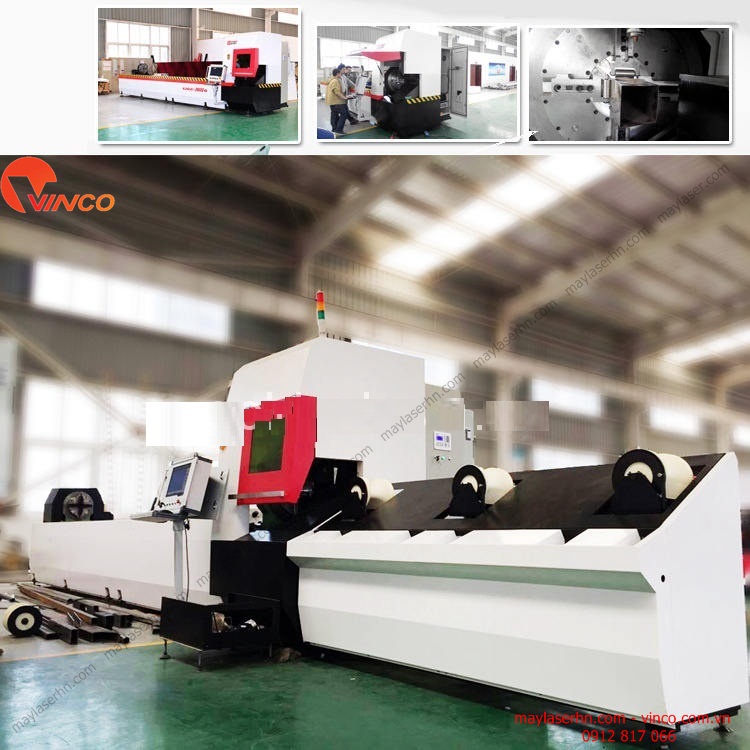

Máy Laser Fiber ST-20600G-700W cắt ống kim loại

Máy Laser Fiber ST-20600G-700W cắt ống kim loại

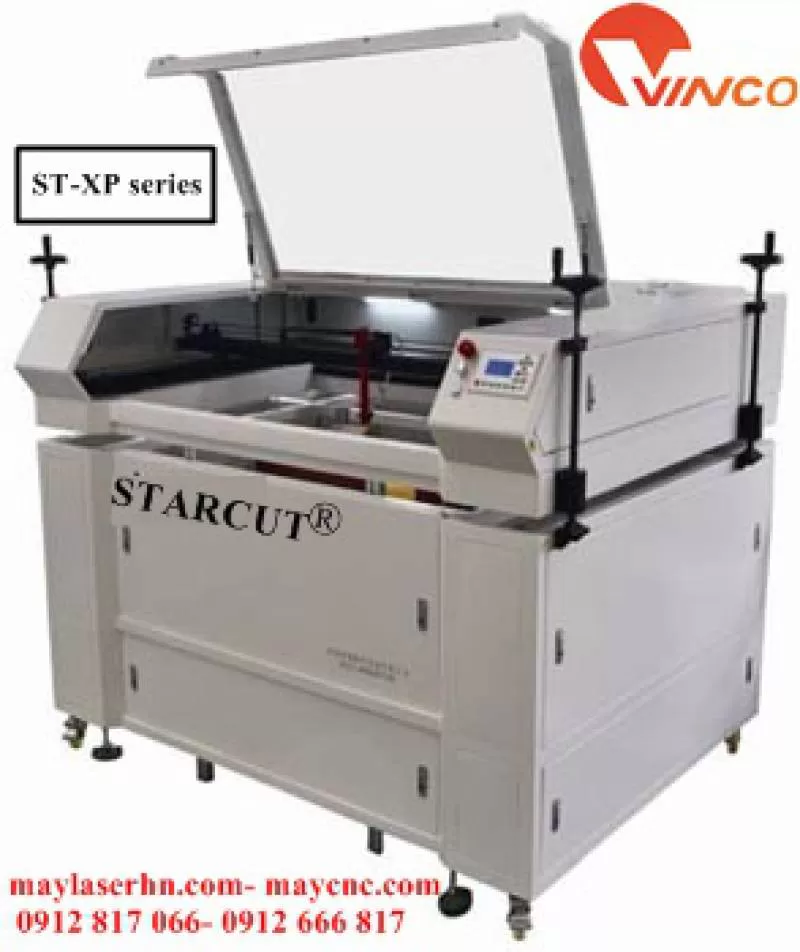

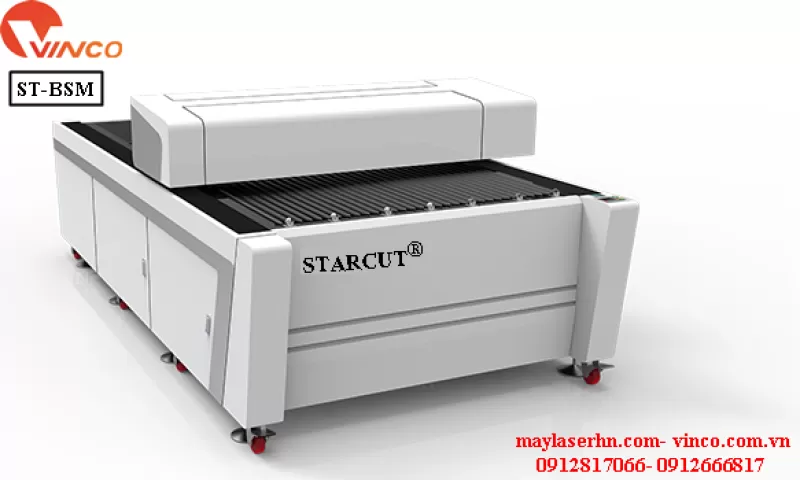

Các đề xuất khác cho doanh nghiệp của bạn

Những điểm chính về sản phẩm

Thuộc tính cụ thể của ngành

Các thuộc tính khác

Mô tả sản phẩm từ nhà cung cấp

Mô tả sản phẩm

Thông tin chi tiết

Máy Laser Fiber ST-20600G-700W cắt ống kim loại

Laser tube cutting machine with 700 watt IPG fiber laser.

Maximum cutting wall thickness 8mm carbon steel, 5mm stainless steel, 3mm aluminum, 3mm brass, 3mm copper.

Cutting round, square, rectangular, oval, waist round metal pipe & tube, etc.

Pipe / tube processing, Φ=20mm~200mm, L=6m for standard. Φ=200mm~300mm, L>6m for option.

Laser Tube Cutting Machine Function

1) It can cut multiple different diameter of intersecting line of cylinder in different directions. Then it can makes branch pipe axis eccentric/concentric vertical intersect main pipe axis.

2) In the branch pipe end cutting cylinder intersecting end, meet the vertical axis and axis condition branch director and non eccentric inclined intersect.

3) It can cut obligue section on the end of pipe

4) Can the intersecting line cutting intersecting ring main branch pipe end.

5) It can cut for various-angle groove face

6) It can cut with square & oval hole on the square pipe

7) Cut off steel cylinder pipe

8) Can cut a variety of graphics in square tube surface

Laser Tube Cutting Machine Main Features

1).Exclusive innovation developed jaw opening and closing system, can achieve the clamping action of the workpiece by intelligent simulation Manual adjustment process and the clamping force can be adjusted very convenient stepping relax workpiece clamping the device than the traditional pneumatic chuck low cost and the total cost over the SIEMENS system (Han chuck) low currently the device Golden Laser has applied for patent

2).The device adopts multiple automatically segmented feeding method, feeding precise and convenient, reducing the after-sales maintenance cycles It can also adapt to harsh working environments.

3).Quick clamping connector tube ends is an exclusive innovation invention. The device is not only fast and easy for clamping to reduce the distance from laser processing head to the pipe ends, but also can be expected to save customers’ the ends of the head tube, reducing the material head waste, improve material utilization full

4).Air system can simultaneously access three different auxiliary gas, and automatic conversion. High-pressure gas path designed to improve the capacity of cutting of stainless steel and other hard materials. Through the solenoid and proportional valves can automatically switch oxygen, nitrogen and air, and the gas pressure can be within a certain range stepless adjustment

5).Machine design elegant appearance, security good; system more user-friendly design, high degree of automation, easy operation, while reducing labor and personnel labor intensity.

6).Equipment optimized design, the whole weight of machine is lighter than relatively products, easy to transport, installation and commissioning The overall manufacturing process is simple, reliable, cost-effective equipment in general.

7).Rotating part of the ordinary four-jaw chuck, the quality of the disc is lighter than air card, a small amount of inertia in the reverse rotation of the fast reaction speed, cutting time-saving, reducing the relative error caused by the moment of inertia. It can change gripping diameter of the workpiece. The processing time of each batch variation in the diameter range without replacing the pipe clamp jaws can be realized in a single setup, significant savings in time replace the claw.

8).For all types of large diameter tolerances, fuzzy boundaries, stepping device selectively gripping and pre-set torque to ensure the holder is not easy deformation of thin-walled tube.

Cutting Thickness Limit

| Material | Cutting Thickness Limit |

| Carbon steel | 8mm |

| Stainless steel | 5mm |

| Aluminum | 3mm |

| Brass | 3mm |

| Copper | 2mm |

Speed Chart

| Material | Thickness (mm) | Cutting speed (m/min) | Gas |

| Carbon steel | 1 | 13 | O2 |

| 2 | 6 | O2 | |

| 3 | 2.4 | O2 | |

| 3.5 | 1.8 | O2 | |

| 6 | 1.2 | O2 | |

| 8 | 0.9 | O2 | |

| Stainless steel | 1 | 12 | N2 |

| 2 | 4.5 | N2 | |

| 3 | 1 | N2 | |

| 4 | 0.4 | N2 | |

| 5 | 0.2 | N2 | |

| Aluminum | 1 | 5.4 | Air |

| 2 | 2.1 | Air | |

| 3 | 0.8 | Air | |

| Brass | 1 | 4.8 | Air |

| 2 | 2.2 | Air | |

| 3 | 0.7 | Air |

700W IPG Pipe / Tube Fiber Laser Cutting Machine ST-20600G-700W

Main Parts

| Article Name | Remark |

| Fiber laser resonator | IPG 700W (America/Russia) |

| Servo motor and driver | YASKAWA (Japan) |

| Ball screw rod | HIWIN (Taiwan) |

| Gear rack | ATLANTA (Germany) |

| Laser head | PRECITEC (Germany) |

| Chiller | TONG FEI (China) |

| Control system | FSCUT (China) |

| Z axis Height controller | FSCUT (China) |

| Liner guide | HIWIN (Taiwan) |

| Gas Proportional valve | SMC (Japan) |

| Reduction gear box | APEX (Taiwan) |

| Rotate chuck | Golden Laser OEM |

| Roller support with scale | Golden Laser OEM |

| Machine metal body | Golden Laser |

700W IPG Pipe / Tube Fiber Laser Cutting Machine ST-20600G

Technical Specification

| Laser power | 700W |

| Laser source | America/Russia IPG fiber laser resonator |

| Pipe/Tube processing (Φ x L) | Φ=20-200mm, L=6m (Φ=20-300mm for option; L>6m for option) |

| Pipe/Tube category | Round, square, rectangular, oval, waist round, etc |

| Rotate speed | 90 turn/minute |

| CNC control | Shanghai FSCUT CypTube |

| Laser head | Germany PRECITEC LightCutter |

| Power supply | AC380V±5% 50/60Hz (3 phase) |

| Total electric power | 16KW |

| Position accuracy | 0.3mm |

| Repeat position accuracy | 0.1mm |

| Maximum position speed | 70m/min |

| Acceleration | 0.8g |

| Drawing programming mode | Solidworks、Pro/e、UG, etc import directly |

| Machine weight | 6T |

| ***Note: As products are constantly updated, pleasecontact usfor latest specifications.*** | |

Tube Laser Cutting Applicable Material

Stainless steel, carbon steel, mild steel, alloy steel, spring steel, copper, aluminum etc.

Tube Laser Cutting Applicable Industry

CNC tube laser cutting machine has been widely used in different kinds of manufacturing and processing lines:spare parts of fitness equipment, furniture, agricultural and forestry machinery, decorative lighting, automobile industry, textile machinery, food machinery, metal artwork crafts, spectacle frame, etc.

Công ty chúng tôi rất hân hạnh được hợp tác và phục vụ Quý khách hàng.

Mọi thông tin chi tiết Quý khách vui lòng liên hệ:

Công ty TNHH Đầu Tư Quốc Tế Việt Nam

Đ/c: Số 18BT4-1 khu đô thị Trung Văn, Nam Từ Liêm, Hà Nội

Tell: 04 3566 6727 - 04 4450 8666 _ Hotline: 0912 817 066 - 0901 754 566

Website: maylaserhn.com - vinco.com.vn