HFP530A Concrete Wall Panels Prices Precast Concrete Slabs Eps Wall Panel Machine Construction and Building Machinery

HFP530A Concrete Wall Panels Prices Precast Concrete Slabs Eps Wall Panel Machine Construction and Building Machinery

Các đề xuất khác cho doanh nghiệp của bạn

Những điểm chính về sản phẩm

Thuộc tính cụ thể của ngành

Các thuộc tính khác

Mô tả sản phẩm từ nhà cung cấp

Mô tả sản phẩm

over dimensions | 3380*3200*2680mm |

weight | 7200kg |

finished panel size | 2440*610*60-200mm |

hydraulic unit power | 2.2kw |

molding time | 6-8hour |

charging volume | 5m² |

number of pallet provided per time | 40pcs / thickness 60mm |

36pcs / thickness 75mm | |

32pcs /thickness 90mm | |

30pcs / thickness 100mm | |

26pcs / thickness 120mm | |

24pcs /thickness 130mm | |

22pcs / thickness 150mm | |

installed capacity | 65kw |

Vertical Manual Forming Machine:

Horizontal Forming Machine:

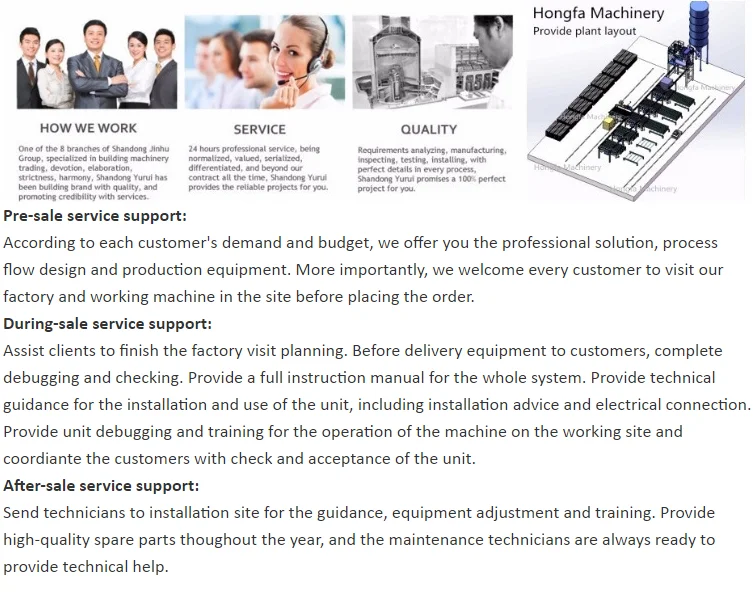

advantages of the production system.

support machine.

Mobile De-Moulding Turnover Platform.

Mobile Injection Machine

Use the advantages of EPS light weight wall panel .

2. Easy and Faster Construction

3. High Hanging Strength

4. Fire Resistant Sound Insulation and absorption capacity

5. Water Proof and Damp proof

6. Low Shrinkage

7. Smooth and Flat Surface

8. Environment-friendly and Non-toxic

9. Increased Net Area which saves money

10. Light weight and earthquake proof

11. Energy saving environment friendly

12. Total Quality Control & Anti-Manipulation construction

13. Permeability Resistance

FAQ.