Automatic Small AAC Block Making and Cutting Machine with Core Components Engine and PLC

(12 Lượt)

Công ty TNHH Máy móc hạng nặng Quảng Tây Hongfa

Nhà sản xuất, chế tạo • 2 năm

VN

VN

Automatic Small AAC Block Making and Cutting Machine with Core Components Engine and PLC

Các đề xuất khác cho doanh nghiệp của bạn

Những điểm chính về sản phẩm

Thuộc tính cụ thể của ngành

Các thuộc tính khác

Khu vực

Thương hiệu

Mã sản phẩm

Tên sản phẩm

Automatic Small AAC Block Making and Cutting Machine with Core Components Engine and PLC

Nhà cung cấp

Công ty TNHH Máy móc hạng nặng Quảng Tây Hongfa

Mô tả sản phẩm từ nhà cung cấp

Mô tả sản phẩm

Product Description

Aac Block Making Machine Plant Aac Block Making Machine Aac Block Machine Production Line

Introduction of Aac Flyash Light Brick Making Machine

Hongfa has developed, produced and sold autoclaved aerated blocks(AAC) and autoclaved aerated panels(ALC) production line

equipment since 2007, with an annual production capacity of 50-500 thousand M3, Up to now, moer than 100 production lines have

been sold at home and abroad, ranking among the top manufacturers for domestic production and sales of aerated block equipment.

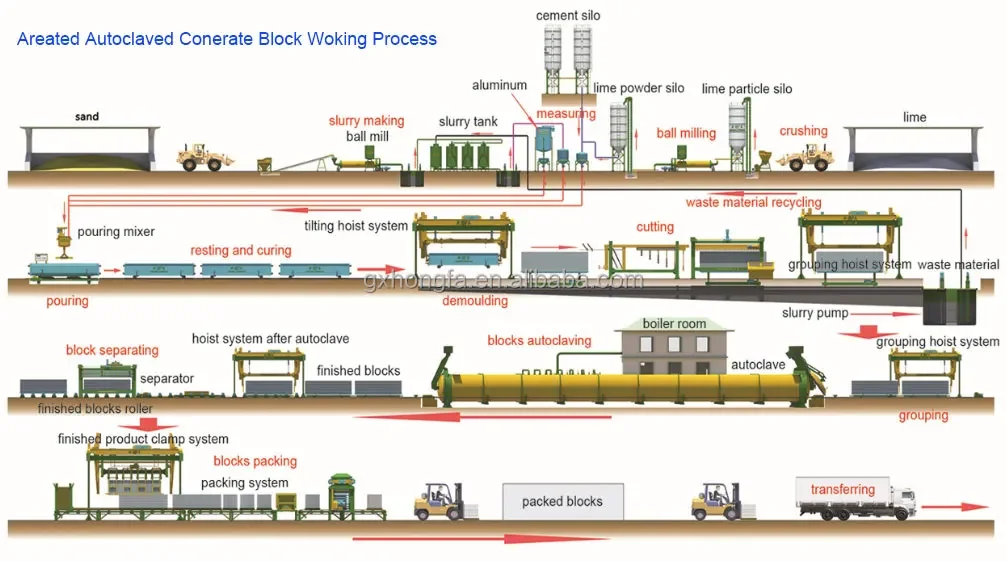

Batching, mixing and pouring process

The lime, cement will convey by conveyor to the dry powder measure scale to scale separately. The slurry convey by slurry pump then to the automatic scale;the power and slurry put into the mixer,pouring into the mould.

Cutting process

Cutting size can be adjusted flexibly, with 0 broken rate.

Finished block dealing process

After 6-10 hours, finished products come out of autoclave, with separting machine to separate blocks layer by layer.

Using finished block carry hanger clamp the finished product to package line on wooden pallets,after package, then by forklift

transport the finished products to piled yard according to specifications to stack.

transport the finished products to piled yard according to specifications to stack.

Specification

The Raw Materials Proportion Of AAC Block A:Contains cement, lime, fly ash, ect. B: Contains cement, lime, sand, ect. | ||||||||

Cement, lime, fly ash style aerzted block raw material proportion | ||||||||

Name | Unit | Proportion | ||||||

Fly ash | % | 65-70 | ||||||

Cement | % | 6-15 | ||||||

Lime | % | 18-25 | ||||||

Gypsum | % | 3-5 | ||||||

Aluminum power paste(600kg/m3) | 1/10000 | 8 | ||||||

Water & material rate | 0.60-0.65 | |||||||

Cating system | ℃ | 36-40 | ||||||

Aluminum mixing time | S | 30-40 | ||||||

Cement, lime, sand style aerzted block raw material proportion | ||||||||

Name | Unit | Proportion | ||||||

Sand | % | 55-65 | ||||||

Cement | % | 10-20 | ||||||

Lime | % | 20-30 | ||||||

Gypsum | % | 2-3 | ||||||

Aluminum power paste(600kg/m3) | 1/10000 | 8 | ||||||

Water & material rate | 0.65-0.75 | |||||||

Cating system | ℃ | 35-38 | ||||||

Aluminum mixing time | S | 30-40 | ||||||

Aac Block Making Machine Brick Making Machinery Concrete Block Home Based Data Entry Jobs

07. Ball mill 08. Slurry storage tank 09. Bactching system 10. Mixing and pouring machine

11. Pouring ferry trolley 12. Mould 13. Grouping conveyance mechanism

14. Cutting machine 15. Rolling-over table 16. Side plate 17. Turnover conveyor device and tilting hoist 18. Steam Generating system(boiler)

19. Autoclave 20. Steam distribution system

21. production conveyor device and production hoist

22. Clamping and conveying mechanism for finished product

23. Conveying mechanism for wooden pallets

24 Roller conveyor for side panel

Aac Block Making Machine Brick Making Machinery Concrete Block Home Based Data Entry Jobs

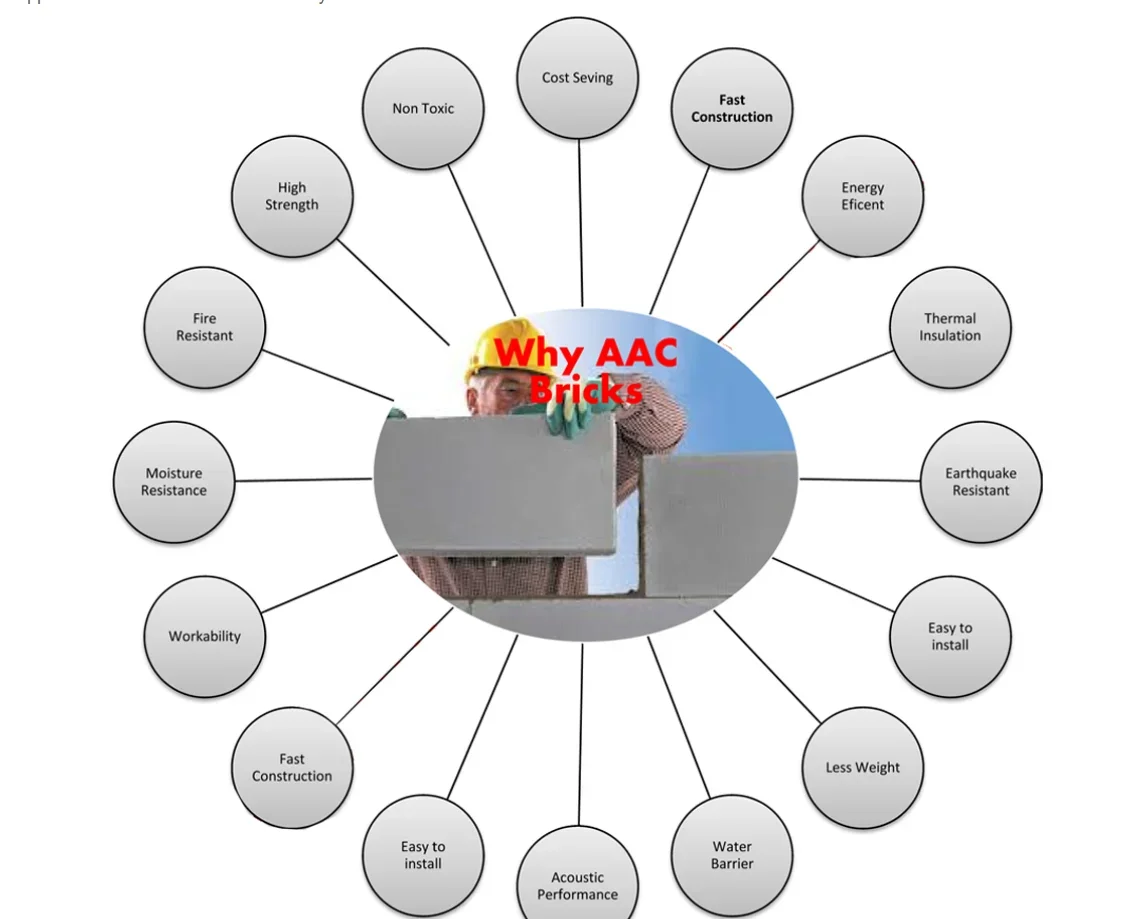

1. Sound proof

2. Thermal Insulation

3. Earthquake Resistant

Earthquake forces on structure are proportional to the weight of the building, hence AAC shows excellent resistant to earthquake

forces.

4. Floor Space Area

Use of thinner blocks (6" instead of 9" exterior walls) because of its excellent water barrier & insulation properties leads to an

increase in floor space area between 3-5%.

5. Cost saving

Being lightweight AAC drastically reduces the dead weight of building, resulting into reduction in steel (up to 27%) and cement

(up to 20%) structural cost saving. Being 8 times the size of a clay brick, AAC wall construction involves 1/3 the joints, thus an

overall mortar saving up to 66%.

6. Fire Resistant

Best in class fire rating of 4 hours. The melting point of AAC is over 1600 ºc, more than twice the typical temperature in a

building fire of 650 ºc.

7. Pest Resistant Termites hate AAC!

Being made of inorganic minerals, it does not promote growth of molds.

8. Water Barrier

Its structure does not allow for capillary action making it impervious to water. Its water barrier properties are further enhanced

by adding silicone based additives.

9. Energy Efficient

AAC is 100% Green Building Material & is a walling material of choice in LEED certified buildings (ITC centre, the highest rated

Green Building has been built using AAC).AAC is most energy & resource efficient in the sense that it uses least amount of energy& material per m³ of product.

10. Light Weight

AAC block density is usually 400-700kg/m3, 1/3 of clay block, 1/5 of common concrete block. 40% lower than the ordinary building

naterials.

11. High Strength

High strength can reach 40kg/square centimeters(about 4.0Mpa). Sand type AAC block normally is 3.8-4.2Mpa, Fly ash type AAC blocks about 3.0-3.5Mpa.

AAC block density is usually 400-700kg/m3, 1/3 of clay block, 1/5 of common concrete block. 40% lower than the ordinary building

naterials.

11. High Strength

High strength can reach 40kg/square centimeters(about 4.0Mpa). Sand type AAC block normally is 3.8-4.2Mpa, Fly ash type AAC blocks about 3.0-3.5Mpa.

Finished Products and Application

Packing & Delivery

Packing: Suitable for road or sea way, standard packing. Naked packing or stretch film packing or according to customers'requirements.

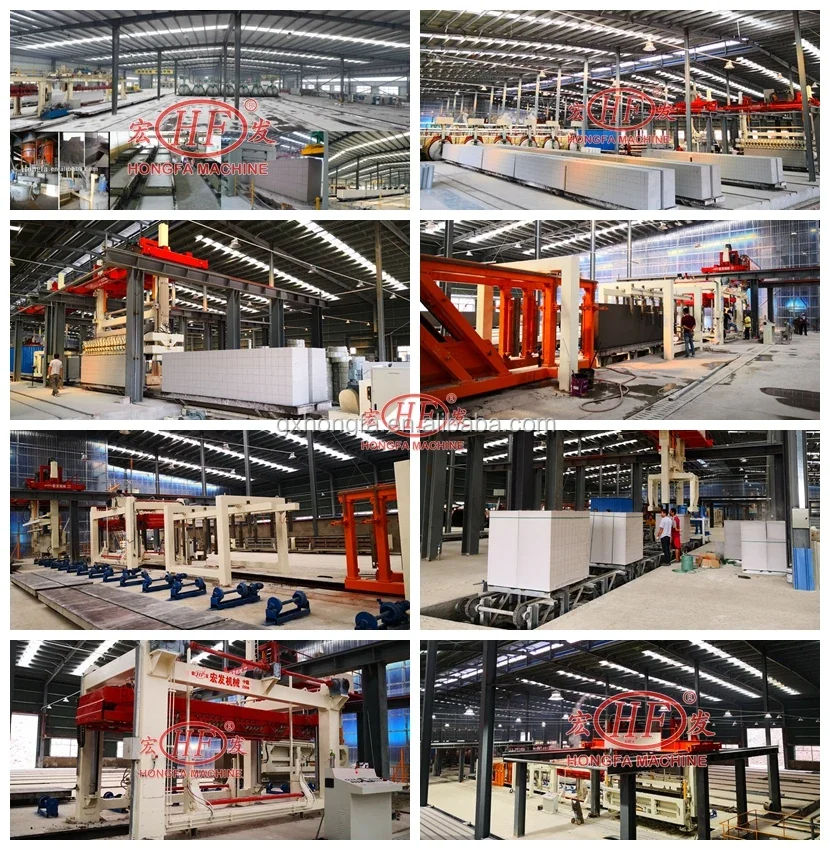

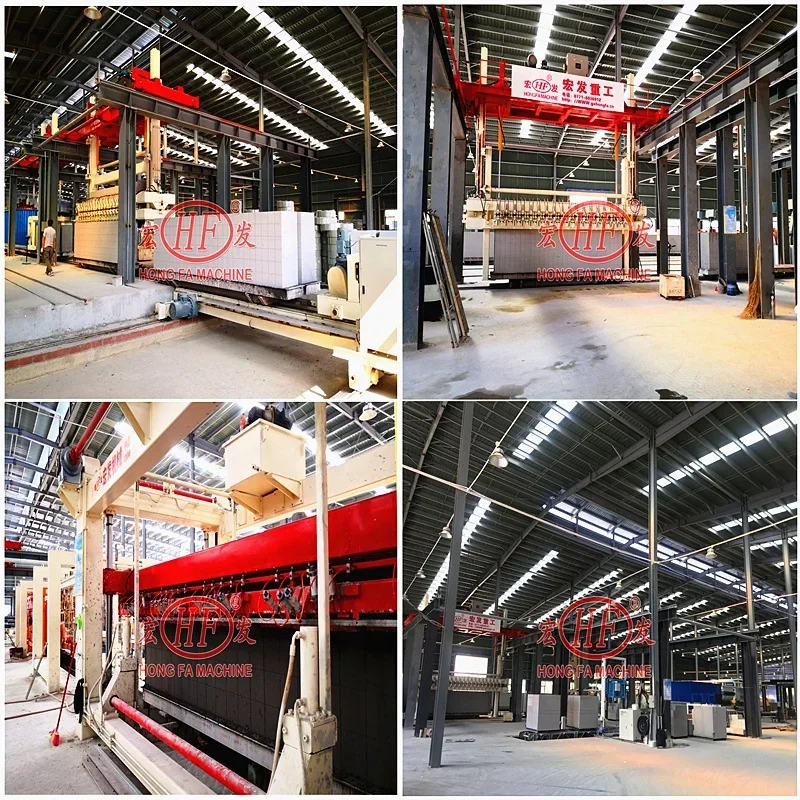

Company Profile

Hongfa Group Established in 1990.

A leader developer& Manufacturer of Construction Material Machinery.

Main business Range & Products:

Lightweight Panel Production Line, AAC Block Production Line, Full Automatic Concrete Block Production Line, Artificial Quartz Plate Production Line, Concrete Pipe Machine, Concrete Tile Machine, Concrete pipe machine, Bidirectional Hydraulic Brick Maker, Mining Machinery, Concrete Batching plant, Stereo Parking Equipment, etc.

Hongfa Strengths

A leader developer& Manufacturer of Construction Material Machinery.

Main business Range & Products:

Lightweight Panel Production Line, AAC Block Production Line, Full Automatic Concrete Block Production Line, Artificial Quartz Plate Production Line, Concrete Pipe Machine, Concrete Tile Machine, Concrete pipe machine, Bidirectional Hydraulic Brick Maker, Mining Machinery, Concrete Batching plant, Stereo Parking Equipment, etc.

Hongfa Strengths

1) More than 30 years experience. 1500 employee (50+engineers)

2) Total 4 factories with 440,000M2 and annual sell above USD100 Million .

3) 10,000 customers and fulfillment to over 120 countries.

4) Continuous service and logistics system.

5) High quality products and competitive price.We hope we can cooperate with each other and establish a win-win business relationship.

2) Total 4 factories with 440,000M2 and annual sell above USD100 Million .

3) 10,000 customers and fulfillment to over 120 countries.

4) Continuous service and logistics system.

5) High quality products and competitive price.We hope we can cooperate with each other and establish a win-win business relationship.

1.One of Top Ten Influential Brands in China Brick &Tile Industry

2.China National Enterprise Abiding By Contract & Keeping Good Faith

3.Quality and Credibility of the Dual-protection Demonstration Unit

4.High and New Technology Enterprise

5.Famous Trademark of China

6.Star Enterprise with China Patent

7.AAA Grade Credit Enterprise

8.Consumer Satisfaction Unit

9.One of Top 100 building Material Industry Brands of China

10.One of Top Ten Good Faith Units

11.Advanced Exporter in Guangxi Province

12.Advance Quality Management Unit

2.China National Enterprise Abiding By Contract & Keeping Good Faith

3.Quality and Credibility of the Dual-protection Demonstration Unit

4.High and New Technology Enterprise

5.Famous Trademark of China

6.Star Enterprise with China Patent

7.AAA Grade Credit Enterprise

8.Consumer Satisfaction Unit

9.One of Top 100 building Material Industry Brands of China

10.One of Top Ten Good Faith Units

11.Advanced Exporter in Guangxi Province

12.Advance Quality Management Unit

FAQ

1. Can this machine make my brick or other size block?

We would design and do the mould according to customer's Drawing.

2. Are your company is the manufacture or trading company?

We would design and do the mould according to customer's Drawing.

2. Are your company is the manufacture or trading company?

We are Direct factory,not agent or trading company,and the quality and after-sale services is quaranteed.

3.How can I trust the machines quality?

Our products passed ISO9001-2000 and CE identifications, we started produce different types of concrete block machines for 29 years since 1990, with rich industry experience, we are always keeping technics updating. Furthermore our machines have been exported to more than 96 countries and always have a good reputaion from our oversea customers. We test all the machines before shipping, make sure every machine works well when they delivered.

4. When do you delivery the goods?

Normally 30 days after receipt of deposit and moulds confirmation from Buyer.

5. What about the payment terms?

30% as down deposit by T/T ,70% as the balance paid by T/T before loading(L/C is also acceptable).

6. Would you mind provide the video?

The video is available to send to you, please contact me.

7. How about the commissioning of the machine and training to workers?

Yes, after finish the installation of the block production line, our engineer will do the testing and commissioning, and make the most suitable ratio of the materials to make the blocks, and train the workers how to operate and maintain the machines.

Our products passed ISO9001-2000 and CE identifications, we started produce different types of concrete block machines for 29 years since 1990, with rich industry experience, we are always keeping technics updating. Furthermore our machines have been exported to more than 96 countries and always have a good reputaion from our oversea customers. We test all the machines before shipping, make sure every machine works well when they delivered.

4. When do you delivery the goods?

Normally 30 days after receipt of deposit and moulds confirmation from Buyer.

5. What about the payment terms?

30% as down deposit by T/T ,70% as the balance paid by T/T before loading(L/C is also acceptable).

6. Would you mind provide the video?

The video is available to send to you, please contact me.

7. How about the commissioning of the machine and training to workers?

Yes, after finish the installation of the block production line, our engineer will do the testing and commissioning, and make the most suitable ratio of the materials to make the blocks, and train the workers how to operate and maintain the machines.

Contact us

Giá

2,147,483,647 đ

Shipping/Vận chuyển

Dịch vụ chuyển phát nhanh toàn quốc (Tiêu chuẩn)

Thời gian giao hàng: Liên hệ

Bảo vệ cho sản phẩm này

Giao hàng qua Daisan Logistics

Giao hàng qua Daisan Logistics

Dự kiến đơn hàng của bạn sẽ được giao trước ngày dự kiến hoặc nhận khoản bồi thường chậm trễ 10%

Thanh toán an toàn

Thanh toán an toàn

Mọi khoản thanh toán bạn thực hiện trên Daisan.vn đều được ...

Chính sách hoàn tiền

Chính sách hoàn tiền

Yêu cầu hoàn lại tiền nếu đơn đặt hàng của bạn không được vận chuyển, bị thiếu hoặc giao đến có vấn đề về sản phẩm

Sản phẩm khác cùng danh mục

Sản phẩm có thể bạn quan tâm

Sản phẩm phổ biến của nhà cung cấp

Eps Kpk Imento Tula Yapma Plaka Makinasi Construction Machinery Light Foam Cement

Liên hệ

1 piece (Tối thiểu)

Concrete Fence Post Mould Concrete Slabs Precast Walls Board Machine Concrete Fence Post Mould Concrete Fences Moulds

625,000,000đ

1 piece (Tối thiểu)

Terrazzo Machine Paver Block Mould for Plastic Construction Machinery Castings

375,000,000đ

1 piece (Tối thiểu)

Terrazzo Stone Slab Best Selling Products in Africa Kenya New the Usa Popular China Full Automatic Provided

Liên hệ

1 piece (Tối thiểu)

Marble Mosaic Cement Concrete Terrazzo Press Machine Terrazzo Artificial Floor Tile Making Machine

Liên hệ

1 piece (Tối thiểu)

2024 New Design Jesmonite Terrazzo Powder and Liquid Artificial Terrazzo Stone Production Line Sale Price

Liên hệ

1 piece (Tối thiểu)

MYW-150 Concrete Terrazzo Ceramic Roof Floor Cement Tile Making Machine Price

Liên hệ

1 piece (Tối thiểu)

Terrazzo Marble Mosaic Tile Bathroom Decorative Tile Interior Wall Flooring Mosaico Terrazzo Tile Making Machine

Liên hệ

1 piece (Tối thiểu)