Automatic Artificial Quartz and Marble Slab Making Machine Counter Plate Production Line with Engineer Overseas Installation

(13 Lượt)

Công ty TNHH Máy móc hạng nặng Quảng Tây Hongfa

Nhà sản xuất, chế tạo • 2 năm

VN

VN

Automatic Artificial Quartz and Marble Slab Making Machine Counter Plate Production Line with Engineer Overseas Installation

Các đề xuất khác cho doanh nghiệp của bạn

Những điểm chính về sản phẩm

Thuộc tính cụ thể của ngành

Các thuộc tính khác

Khu vực

Thương hiệu

Mã sản phẩm

Tên sản phẩm

Automatic Artificial Quartz and Marble Slab Making Machine Counter Plate Production Line with Engineer Overseas Installation

Nhà cung cấp

Công ty TNHH Máy móc hạng nặng Quảng Tây Hongfa

Mô tả sản phẩm từ nhà cung cấp

Mô tả sản phẩm

Product Description

Artificial Quartz and Marble Slab Making Machine Production Line

Brief introduce

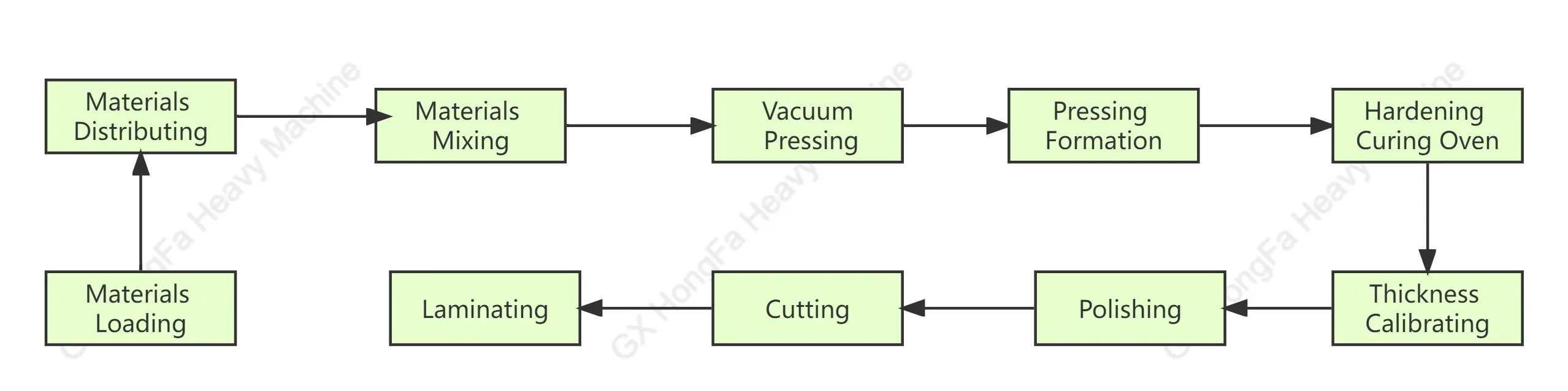

This is an Automatic Quartz Stone/Slab/Panel production line. It produces various specifications and patterns of artificial quartz slabs with different colors and designs.The main configuration and machine of the quartz stone production line are as follows:

1. Materials mixing system

2. Materials distributing system

3. Automatic vacuum pressing machine

4. Hardening curring oven

5.The thickness machine

6. Polishing machine

7. Cutting machine

8. Laminating machine, etc.

1. Materials mixing system

2. Materials distributing system

3. Automatic vacuum pressing machine

4. Hardening curring oven

5.The thickness machine

6. Polishing machine

7. Cutting machine

8. Laminating machine, etc.

Product Parameter

Specifications for Hongfa Quartz slab making machine | ||||||||

Product size | 1900 x 3300mm MAX. | Slab type | abinet veneer, floor veneer, stair | |||||

Molding cycle | 120S | Power | 41KW | |||||

Capacity | 90pcs / 8 hours(1 shift) | Dimension | 5560 x 2680 x 2400 mm | |||||

Quantity/ mold | 1 pc | Weight | 19T | |||||

Relevant machinery: Mixer, mould(s), drying room, calibrating machine, grinding machine, cutting machine etc. | ||||||||

1. Raw material

The main raw materials for making the Artificial Quartz Stone commonly are:

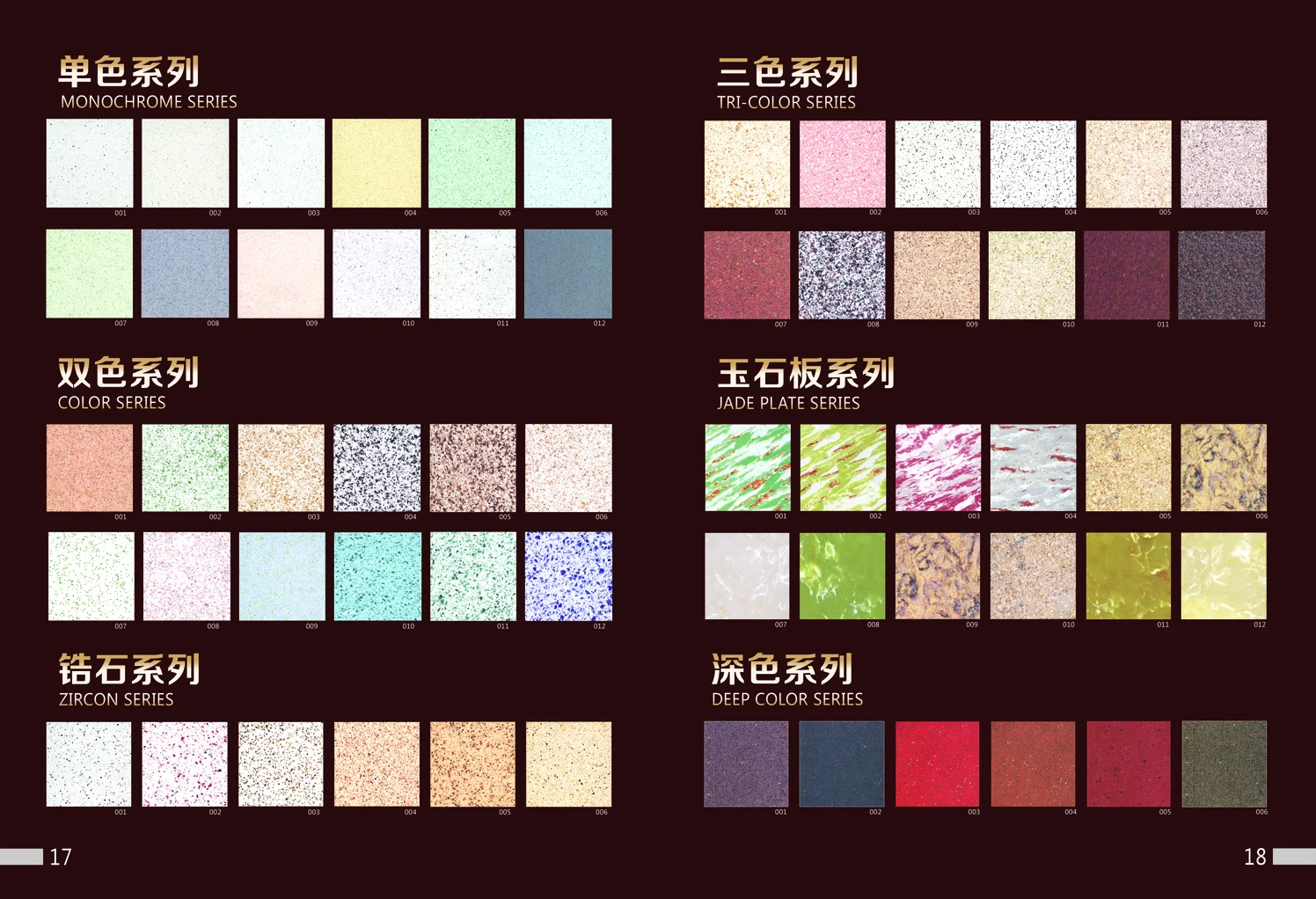

Quartz sand, quartz powder, resin, titanium dioxide, and additives. Marble chips, Granite Chips, and Glass chips also can be added to make special patterns.

Quartz sand, quartz powder, resin, titanium dioxide, and additives. Marble chips, Granite Chips, and Glass chips also can be added to make special patterns.

2. Advantages of the Quartz Stone, Quartz Slab, and Quartz Plate

1) Eco-friendly material, non-radiation to health, non-melamine.

2)Anti-bacteria, and chemical resistant, high plasticity, nearly zero water absorption.

3) Easy maintenance; can be renewable after a long time of use.

3) Easy maintenance; can be renewable after a long time of use.

3. Application of the Quartz Slab

kitchen tops, bathroom vanity tops, worktops, laundry, table tops, bench tops, bar tops, backsplashes, shower stalls, tub surrounding tile, wall cladding, floor tile, and airport, station, shopping mall, hotel, bank, hospital, etc.

kitchen tops, bathroom vanity tops, worktops, laundry, table tops, bench tops, bar tops, backsplashes, shower stalls, tub surrounding tile, wall cladding, floor tile, and airport, station, shopping mall, hotel, bank, hospital, etc.

production line

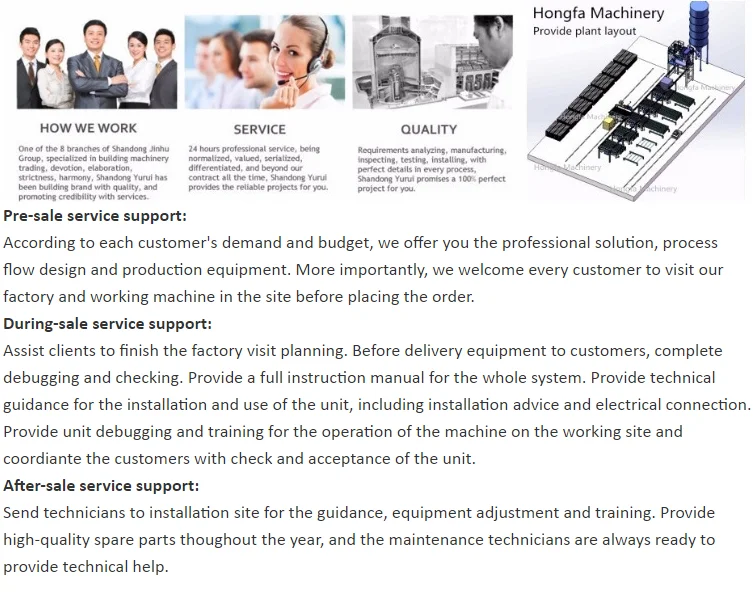

Our service

Our Services.

---Consulting & Planning

---Designing & Manufacturing

---Technology Instructing

---Installation Guiding

---Training&Commissioning

---After-Sales Services Providing

Why Choose Us

1. Won many international awards and recognition due to our performance.

2. All products and machineryare produced as per international standards and duly certified by international agencies and test houses.

3. We are possibly the only company that manufactures everything in the House and not an assembly house.

4. We have our own Testing and Research lab where we keep doing tests to arrive at the best solutions for the problems in products and processes.

5. We provide 24x7 service to our International clients.

6. More than 200 plants working domestic market and the world over made by us of different products.

7. In-house final product production to study the day-to-day problems of the clients and solve them.

8. Provide full technical support to clients in terms of formulations and production.

9. International warranty for the plants supplied by us.

10. In-house or on-the-spot training of the local staff by our trained engineers at clients' cost of course.

We are confident that you will surely be happy to join our family of HONGFAand make use of this opportunity

Our Company

Company Profile.

GUANGXIHONGFA HEAVY MACHINERY CO.,LTDis a leading name in research,design,develop,manufacture of environmental friendly building materials production line machines from the early 1990s.

Main products: Light Weight Cement EPS Wall Panel Production Line Machine, Autoclave Aerated Concrete (AAC)Block Production Line, Concrete Batching Plant, Fully Automatic Concrete Block/Brick Production Line Machine, Concrete Tile Making Machine, Concrete Pipe Making Machine, Non-Vibration Hydraulic Brick Making Machine,Artificial Quartz Stone Production Line Machine,etc.

Our strength: has four production factories and a large Research and Development center. The plant area is 440,000 ㎡ employing 1500 including 40 engineers and 150 assistant engineers. The annual sale is approx. 100 Million USD covering more than 132 countries such as the United States, Russia, Australia, Brazil, India, Vietnam, Thailand, Sudan, North Korea, Angola, Bangladesh,South Africa,Saudi Arabia,Lebanon,Qatar, etc.

Hongfa machinery Honors and Recognition.

-One of Top Ten Influential Brands in China for Brick & Tile Industry

-AAA Grade Credit Enterprise.

-Star Enterprise with China Patent

-China National Enterprise-abiding Contract & Good Faith

-Quality and Credibility of the Dual-protection Demonstration Unit

-Advance Quality Management Unit

-High and New Technology Enterprise

-Famous Trademark of China

-Consumer Satisfaction Unit

-One of Top Ten Good Faith Units

-Advanced Exporter in China

Customer Photos

FAQ.

Q1. Are your company is the manufacture or trading company?

A1. We are Direct factory, not agent or trading company, and the quality and after-sale services is quaranteed.

Q2. When do you delivery the goods?

A2. Normally 30 days after receipt of deposit and moulds confirmation from Buyer.

Q3. What about the payment?

A3. 30% as down deposit by T/T, 70% as the balance paid by T/T before loading(L/C is also acceptable).

Contact Us

Contact Ms. Ivy Liu

Dept manager

Hongfa group since 1990

Email: ivy(at)gxhfmachine.com

WhatsApp: +86 18934977386

Giá

262,025,000 đ

Shipping/Vận chuyển

Dịch vụ chuyển phát nhanh toàn quốc (Tiêu chuẩn)

Thời gian giao hàng: Liên hệ

Bảo vệ cho sản phẩm này

Giao hàng qua Daisan Logistics

Giao hàng qua Daisan Logistics

Dự kiến đơn hàng của bạn sẽ được giao trước ngày dự kiến hoặc nhận khoản bồi thường chậm trễ 10%

Thanh toán an toàn

Thanh toán an toàn

Mọi khoản thanh toán bạn thực hiện trên Daisan.vn đều được ...

Chính sách hoàn tiền

Chính sách hoàn tiền

Yêu cầu hoàn lại tiền nếu đơn đặt hàng của bạn không được vận chuyển, bị thiếu hoặc giao đến có vấn đề về sản phẩm

Sản phẩm khác cùng danh mục

Sản phẩm có thể bạn quan tâm

Sản phẩm phổ biến của nhà cung cấp

Eps Kpk Imento Tula Yapma Plaka Makinasi Construction Machinery Light Foam Cement

Liên hệ

1 piece (Tối thiểu)

Concrete Fence Post Mould Concrete Slabs Precast Walls Board Machine Concrete Fence Post Mould Concrete Fences Moulds

625,000,000đ

1 piece (Tối thiểu)

Terrazzo Machine Paver Block Mould for Plastic Construction Machinery Castings

375,000,000đ

1 piece (Tối thiểu)

Terrazzo Stone Slab Best Selling Products in Africa Kenya New the Usa Popular China Full Automatic Provided

Liên hệ

1 piece (Tối thiểu)

Marble Mosaic Cement Concrete Terrazzo Press Machine Terrazzo Artificial Floor Tile Making Machine

Liên hệ

1 piece (Tối thiểu)

2024 New Design Jesmonite Terrazzo Powder and Liquid Artificial Terrazzo Stone Production Line Sale Price

Liên hệ

1 piece (Tối thiểu)

MYW-150 Concrete Terrazzo Ceramic Roof Floor Cement Tile Making Machine Price

Liên hệ

1 piece (Tối thiểu)

Terrazzo Marble Mosaic Tile Bathroom Decorative Tile Interior Wall Flooring Mosaico Terrazzo Tile Making Machine

Liên hệ

1 piece (Tối thiểu)