Aac Production Line Block Making Machine Lightweight Concrete Machine

(12 Lượt)

Công ty TNHH Máy móc hạng nặng Quảng Tây Hongfa

Nhà sản xuất, chế tạo • 2 năm

VN

VN

Aac Production Line Block Making Machine Lightweight Concrete Machine

Các đề xuất khác cho doanh nghiệp của bạn

Những điểm chính về sản phẩm

Thuộc tính cụ thể của ngành

Các thuộc tính khác

Khu vực

Thương hiệu

Mã sản phẩm

Tên sản phẩm

Aac Production Line Block Making Machine Lightweight Concrete Machine

Nhà cung cấp

Công ty TNHH Máy móc hạng nặng Quảng Tây Hongfa

Mô tả sản phẩm từ nhà cung cấp

Mô tả sản phẩm

Product Overview

Autoclaved Aerated Concrete Block Gas Block Equipment AAC Block Production Line

The AAC production process includes raw material preparation, batching and mixing, pouring, precuring, cutting, autoclaving, and packing.

Hongfa establish in 1990,now has 80 AAC production line plant abroad,With our rich experience and advanced technology, we can supply customers with quality AAC block production lines with capacity ranging from 80,000m3 to 400,000m3 per year.

The AAC production process includes raw material preparation, batching and mixing, pouring, precuring, cutting, autoclaving, and packing.

Hongfa establish in 1990,now has 80 AAC production line plant abroad,With our rich experience and advanced technology, we can supply customers with quality AAC block production lines with capacity ranging from 80,000m3 to 400,000m3 per year.

1. Low density : Can be 325kg /m3

2. Good thermal insulating properties

3. Cost few time to build, saving time

4. Easy to operate , saving labor cost

5. Good performance of preventing fire

6. Good sound-insulation properties

7. Durable , anti-seismic , recyclable

2. Good thermal insulating properties

3. Cost few time to build, saving time

4. Easy to operate , saving labor cost

5. Good performance of preventing fire

6. Good sound-insulation properties

7. Durable , anti-seismic , recyclable

Raw Material Preparation For AAC Plant:

AAC block raw material required performance:

Fly ash: A lot has been said about this raw material in this Project Profile itself. But this Raw material is freely available in

Thermal Power plants. There are no taxes on this item whatsoever. Transportation charges are only to be attended by the

entrepreneur.

Sand (65-70%): The core raw material of AAC product; the main resource of silica-aluminum components; correspond with JC409-91,the clay should less than 4%.

AAC block raw material required performance:

Fly ash: A lot has been said about this raw material in this Project Profile itself. But this Raw material is freely available in

Thermal Power plants. There are no taxes on this item whatsoever. Transportation charges are only to be attended by the

entrepreneur.

Sand (65-70%): The core raw material of AAC product; the main resource of silica-aluminum components; correspond with JC409-91,the clay should less than 4%.

Lime(12-20%): One of the main raw materials of fly ash AAC; the main effect is to provide efficient calcium oxide with cooperation of cement making calcium oxide react with SiO2, Al2O3 in hot water then to produce calcium silicate hydrate. Therefore, lime is also the main resource of strength. Effective calcium oxide of lime should not less than 65%, over 80% is perfect and should accord with JC/T621-1996.

Cement(8-10%): This Project aims to utilize OPC cement as main binder material. It will give faster strength to the bricks,besides giving improved consistent quality. It also ensures a better cost effectiveness for the same. Using OPC will be a standardized practice. The other prime advantages of using OPC (compared to other binders) is it’s easy availability locally through nationwide Retail Network of Cement Companies.

Gypsum(1-2%): Gypsum is the foaming regulator in AAC which dispels quicklime and postpones slurry’s densification.CaSO4 should be more than 70%.

Aluminum Podwer(0.074%): It is the forming agent type and recommendation for supply depend on raw materials and mix formula:A lot has been said about this raw material in this Project Profile itself. But this Raw material is freely available in Thermal Power plants. There are no taxes on this item whatsoever. Transportation charges are only to be attended by the entrepreneur.

Cement(8-10%): This Project aims to utilize OPC cement as main binder material. It will give faster strength to the bricks,besides giving improved consistent quality. It also ensures a better cost effectiveness for the same. Using OPC will be a standardized practice. The other prime advantages of using OPC (compared to other binders) is it’s easy availability locally through nationwide Retail Network of Cement Companies.

Gypsum(1-2%): Gypsum is the foaming regulator in AAC which dispels quicklime and postpones slurry’s densification.CaSO4 should be more than 70%.

Aluminum Podwer(0.074%): It is the forming agent type and recommendation for supply depend on raw materials and mix formula:A lot has been said about this raw material in this Project Profile itself. But this Raw material is freely available in Thermal Power plants. There are no taxes on this item whatsoever. Transportation charges are only to be attended by the entrepreneur.

Main Parts of Production Line

Full View Of The Production Line

Production Process

Raw material preparation

1. Dose and match measured raw materials;

2. After distributing, feed raw material into pouring mixer to make slurry.

2. After distributing, feed raw material into pouring mixer to make slurry.

Reinforcement processing

3.Automatic circulation system for cage assembly frame

4.Mesh cage anti-corrosion drying room

5.Automatic warp and weft rib full wire strip welding machine

6.Cage assembly frame shuttle

7.Mesh cage rigid connection welding 8.machine Net cage anti-corrosion spreader

4.Mesh cage anti-corrosion drying room

5.Automatic warp and weft rib full wire strip welding machine

6.Cage assembly frame shuttle

7.Mesh cage rigid connection welding 8.machine Net cage anti-corrosion spreader

Pouring pre-uperation

9. Through thoroughly mixing, the slurry is poured to mould; ,

10. After pre-curing under a certain temperature and time, the block would reach a certain hardness and prepare for cutting;

Cutting section

11. Tilting hoister would turn over 90 degrees of mould;

12. Then open the mould and separate it from block. And take the block with side plate to the cutting cart;

13. The horizontal cutting machine cuts blocks from both sides.

14. Then the vertical cutting;

Marshalling steaming

15. After cutting, the block is hanged to curing carts with side plate by semi-finished product hoister;

16. Grouping the carts and put them into autoclaves;

17. Curing the blocks under certain temperature and pressure;

18. Carry the finished product out of autoclave by the ferry cart

16. Grouping the carts and put them into autoclaves;

17. Curing the blocks under certain temperature and pressure;

18. Carry the finished product out of autoclave by the ferry cart

Finished product packaging

19. The finished product hoister take the finished product to finished blocks area;

20. The side plate return back through side plate roller;

21. Side plate would be organized with open mould for the next circle.

Main Equipment For AAC Line

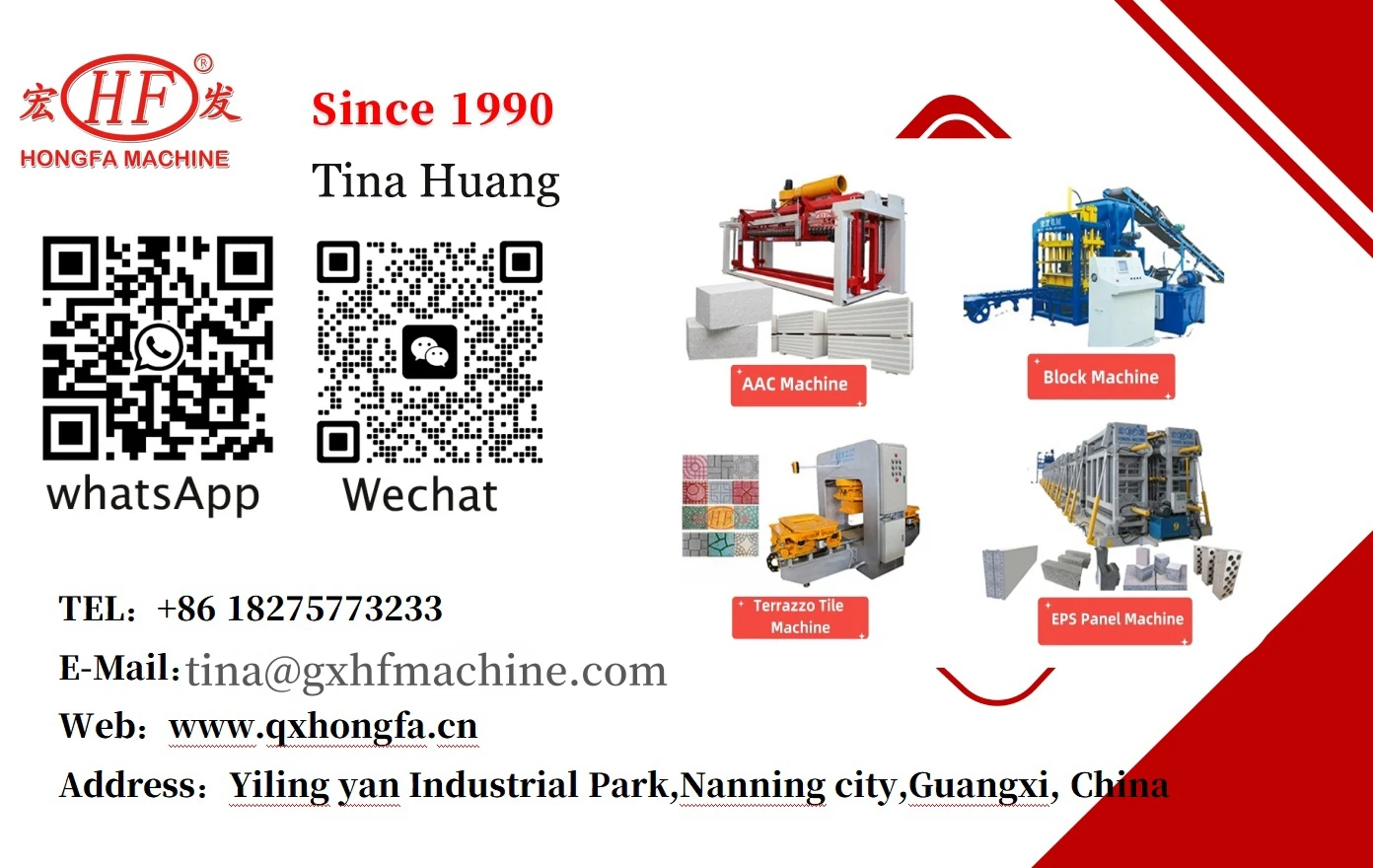

CONTACT Tina :+86 18275773233 | ||||||||

Packing and Shipping

Company Profile

Hongfa Machinery Group

1) More than 34 years experience. 1500 employee (50+engineers) 2) Total 4 factories with 440,000M² and annual sell above USD100 Million .

3) 10,000 customers and fulfillment to over 120 countries.

4) Continuous service and logistics system.

5) High quality products and competitive price.We hope we can cooperate with each other and establish a win-win business relationship.

Exhibitions & Cooperations

Hongfa, as a top brCand enterprise in China, our products are also exported to Russia, Brazil, Thailand, Indonesia,

Vietnam,Angola, Bangladesh, India, Australia, Sudan, etc., 132 countries and regions, deeply welcomed by clients from all around the world.

Vietnam,Angola, Bangladesh, India, Australia, Sudan, etc., 132 countries and regions, deeply welcomed by clients from all around the world.

FAQ

Q: Are you manufacturer or trading company?

A: We are Direct factory, not agent or trading company, the quality and after-sale services is guaranteed.

Q: How long is the warranty of your equipment?

A: 1year

Q: Can this machine make other size product?

A: We would design and do the mould according to customer's Drawing or as ours.

Q: When do you delivery the goods?

A: Normally 30 days after receipt of deposit and moulds confirmation from Buyer.

Q: What about the payment?

A: 30% as down deposit by T/T ,70% as the balance paid by T/T before loading(L/C is also acceptable).

Q: What does the total price include?

A: After some simple communication, we will make the plan according to you target onCapacity and budget. Then we will send the

accurrate quotation for you shortly.

Q: Would you mind provide the video?

A:The video is available to send to you, please contact me.

A: 1year

Q: Can this machine make other size product?

A: We would design and do the mould according to customer's Drawing or as ours.

Q: When do you delivery the goods?

A: Normally 30 days after receipt of deposit and moulds confirmation from Buyer.

Q: What about the payment?

A: 30% as down deposit by T/T ,70% as the balance paid by T/T before loading(L/C is also acceptable).

Q: What does the total price include?

A: After some simple communication, we will make the plan according to you target onCapacity and budget. Then we will send the

accurrate quotation for you shortly.

Q: Would you mind provide the video?

A:The video is available to send to you, please contact me.

Contact Tina Huang

Dear Friends,

Thank you for your visit, my name is Tina from hongfa machinery (since 1990) we have over 34 years experience in the filed of

building machine, And committed to provide the best solutions for our customers. Welcome To contact me Directly

building machine, And committed to provide the best solutions for our customers. Welcome To contact me Directly

+86 18275773233

Giá

2,147,483,647 đ

Shipping/Vận chuyển

Dịch vụ chuyển phát nhanh toàn quốc (Tiêu chuẩn)

Thời gian giao hàng: Liên hệ

Bảo vệ cho sản phẩm này

Giao hàng qua Daisan Logistics

Giao hàng qua Daisan Logistics

Dự kiến đơn hàng của bạn sẽ được giao trước ngày dự kiến hoặc nhận khoản bồi thường chậm trễ 10%

Thanh toán an toàn

Thanh toán an toàn

Mọi khoản thanh toán bạn thực hiện trên Daisan.vn đều được ...

Chính sách hoàn tiền

Chính sách hoàn tiền

Yêu cầu hoàn lại tiền nếu đơn đặt hàng của bạn không được vận chuyển, bị thiếu hoặc giao đến có vấn đề về sản phẩm

Sản phẩm khác cùng danh mục

Sản phẩm có thể bạn quan tâm

Sản phẩm phổ biến của nhà cung cấp

Eps Kpk Imento Tula Yapma Plaka Makinasi Construction Machinery Light Foam Cement

Liên hệ

1 piece (Tối thiểu)

Concrete Fence Post Mould Concrete Slabs Precast Walls Board Machine Concrete Fence Post Mould Concrete Fences Moulds

625,000,000đ

1 piece (Tối thiểu)

Terrazzo Machine Paver Block Mould for Plastic Construction Machinery Castings

375,000,000đ

1 piece (Tối thiểu)

Terrazzo Stone Slab Best Selling Products in Africa Kenya New the Usa Popular China Full Automatic Provided

Liên hệ

1 piece (Tối thiểu)

Marble Mosaic Cement Concrete Terrazzo Press Machine Terrazzo Artificial Floor Tile Making Machine

Liên hệ

1 piece (Tối thiểu)

2024 New Design Jesmonite Terrazzo Powder and Liquid Artificial Terrazzo Stone Production Line Sale Price

Liên hệ

1 piece (Tối thiểu)

MYW-150 Concrete Terrazzo Ceramic Roof Floor Cement Tile Making Machine Price

Liên hệ

1 piece (Tối thiểu)

Terrazzo Marble Mosaic Tile Bathroom Decorative Tile Interior Wall Flooring Mosaico Terrazzo Tile Making Machine

Liên hệ

1 piece (Tối thiểu)